In-home automation, the ESP32 microcontroller from Espressif has become popular for its reliability and versatility. When combined with Norvi products, which offer a range of high-quality industrial automation solutions, the possibilities for creating innovative home automation applications are boundless. This article will delve into 10 Applications with ESP32 HMI to enhance your smart home experience.

Home Automation Applications with ESP32 HMI

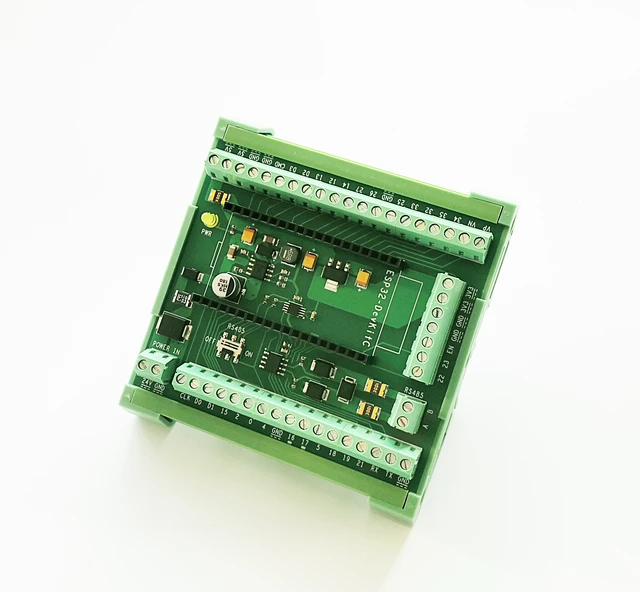

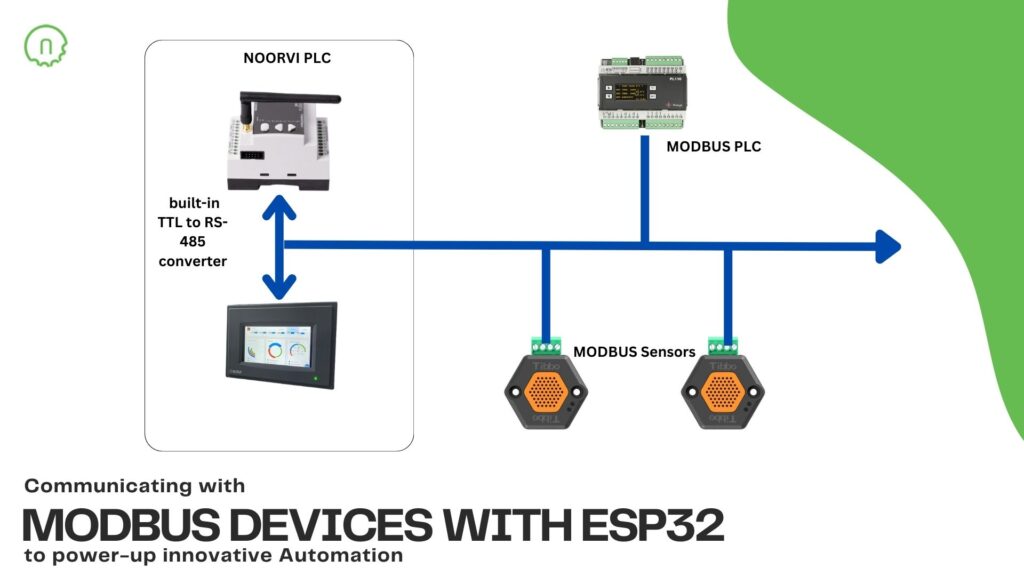

Norvi products bring a myriad of advantages to the realm of home automation, making them a preferred choice for enthusiasts and professionals alike. The industrial-grade reliability of Norvi controllers ensures a robust and durable foundation for smart home applications. Their seamless integration with the ESP32 microcontroller enhances flexibility, enabling users to create tailored automation solutions effortlessly. With a focus on energy efficiency, Norvi products contribute to sustainable living by offering precise control over various devices and sensors. The comprehensive nature of Norvi’s offerings, coupled with their user-friendly interfaces, makes them an ideal choice for creating centralized automation hubs that seamlessly connect and control diverse smart home components. Furthermore, Norvi’s commitment to innovation and quality ensures that users can trust their products to deliver consistent and dependable performance in the ever-evolving landscape of home automation.

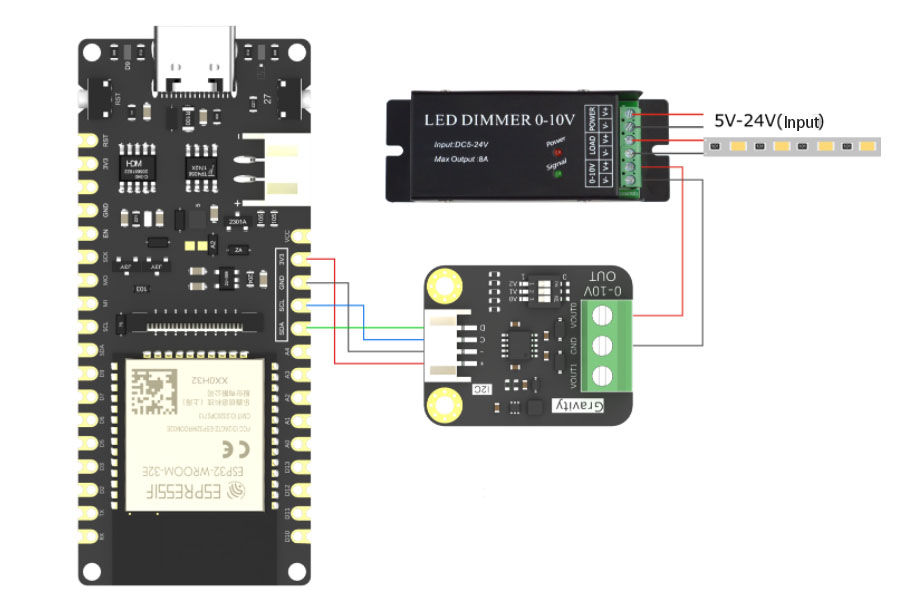

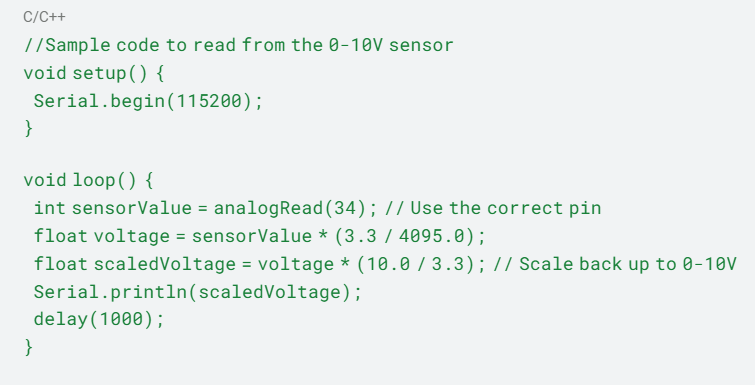

Smart Lighting Control:

- Norvi products can be integrated with ESP32 to create a sophisticated smart lighting system. With features like dimming, color control, and scheduling, users can customize lighting according to their preferences, leading to energy savings and a comfortable living environment.

Temperature and Humidity Monitoring:

- Utilize Norvi products to connect sensors to the ESP32, enabling real-time monitoring of temperature and humidity levels within your home. This application is particularly useful for maintaining optimal conditions in sensitive areas like wine cellars, server rooms, or greenhouses.

Security and Surveillance:

- Transform your home into a secure fortress by integrating Norvi products with ESP32 for surveillance applications. Connect cameras, motion sensors, and door/window sensors to create a comprehensive security system with remote monitoring capabilities.

Automated Irrigation System:

- Norvi’s industrial-grade controllers can be employed for creating an automated irrigation system using ESP32. This solution enables precise control over watering schedules and conditions, ensuring your garden thrives while conserving water.

Energy Management:

- Implement Norvi products alongside ESP32 to monitor and optimize energy consumption. Track electricity usage, control appliances remotely, and even integrate with renewable energy sources for a sustainable and cost-effective home.

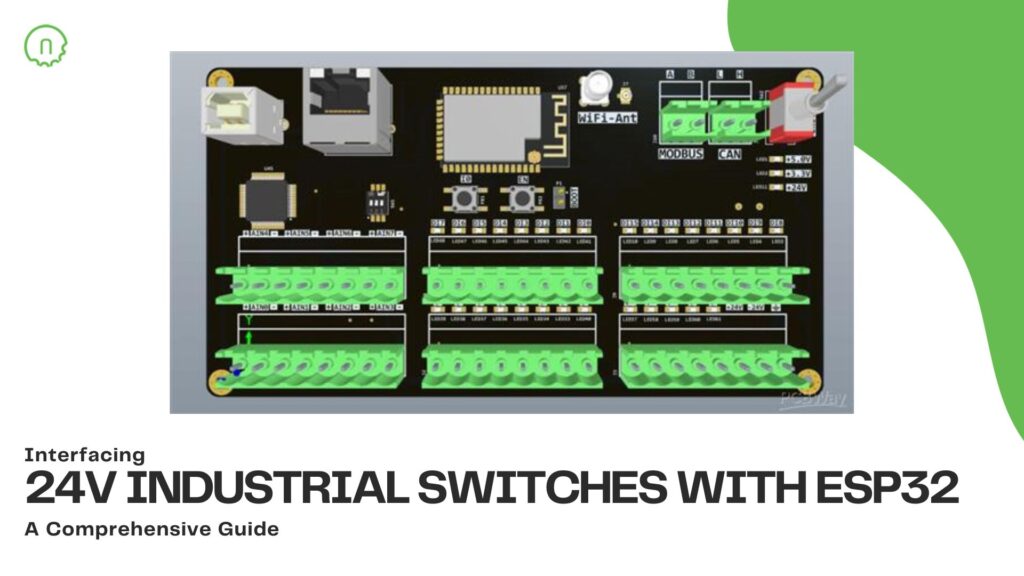

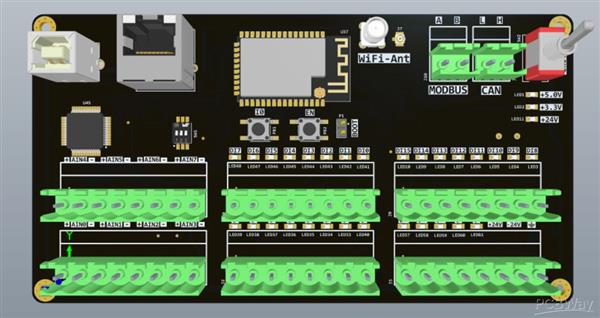

Smart Home Automation Hub:

- Norvi products can serve as the backbone of a centralized home automation hub. The ESP32 acts as the brain, seamlessly connecting and controlling various devices and sensors for a unified smart home experience.

Garage Door Automation:

- Norvi controllers can be employed to automate garage doors, allowing users to open, close, and monitor their garage remotely using the ESP32. Integration with security features enhances the overall safety of your home.

Water Leak Detection:

- Protect your home from water damage by utilizing Norvi products and ESP32 to set up a water leak detection system. Place sensors in vulnerable areas, such as basements or under sinks, and receive instant alerts in case of leaks.

Automated Blinds and Curtains:

- Integrate Norvi controllers with ESP32 to automate blinds and curtains based on environmental conditions or user preferences. This not only adds a touch of luxury but also contributes to energy efficiency.

Voice-Activated Home Automation:

Harness the power of voice control by integrating Norvi products and ESP32 with popular voice assistants. Create a hands-free smart home environment where users can control devices and execute commands using simple voice prompts.

Conclusion

The synergy between Norvi products and the ESP32 microcontroller opens up a world of possibilities for home automation enthusiasts. From basic lighting control to advanced security and energy management, the combination of these technologies empowers users to create a smart home tailored to their unique needs. Whether you are a DIY enthusiast or a professional integrator, Norvi and ESP32 offer a robust platform to turn your home automation dreams into reality. Hope you got clear idea about Applications with ESP32 HMI.

Visit our NORVI Product page to buy devices that suit your home automation projects. https://norvi.lk/products/

If you wanna customize your home automation with customized NORVI products only for you, contact us today at [email protected]