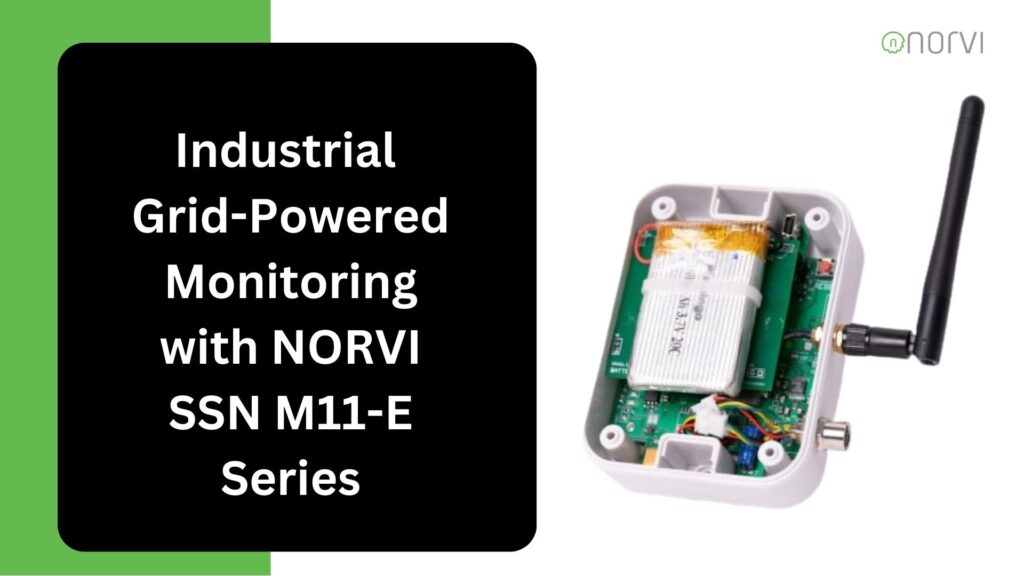

With the advancement of Industry 4.0, the demand for robust, real-time monitoring systems in industrial environments has surged. The NORVI SSN M11-E series, using the ESP32-WROOM32 System on Chip (SoC), presents a potent solution for such applications. This series offers flexible Input/Output (I/O) configurations, a wide input voltage range, and robust communication capabilities, making it ideal for a broad spectrum of industrial monitoring tasks such as Industrial Grid-Powered Monitoring.

Key Features

Versatile I/O Configurations

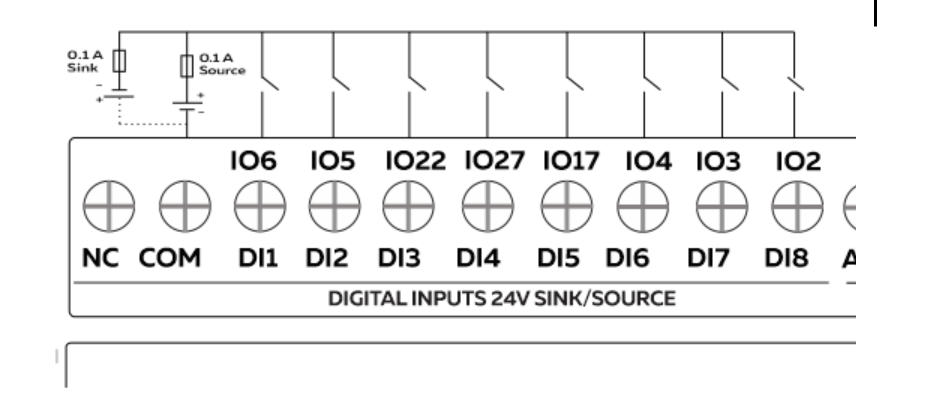

The M11-E series comprises several models, each tailored to specific sensor inputs and communication requirements:

- EC-M11-EG-C1: 2 Digital Inputs, 2 Analog Inputs (0 – 10V DC), 1 RS-485 Communication

- EC-M11-EG-C2: 2 Digital Inputs, 1 RS-485 Communication

- EC-M11-EG-C3: 1 Load Cell Input

- EC-M11-EG-C4: 1 Thermocouple Input

- EC-M11-EG-C5: 1 I2C Communication, 1 3.3V/5V DC Output

Robust Communication

The series supports expansions for GSM/LTE, NB-IoT, and LoRa, ensuring reliable data transmission in diverse environments. Additionally, the RS-485 communication port enables stable, long-distance data transfer within industrial settings.

Wide Input Voltage Range

Operating within a 9 – 36V DC range, the M11-E series can be seamlessly integrated into existing industrial power infrastructures, offering flexibility and ease of deployment.

Industrial Design

Encased in an IP67-rated enclosure, the M11-E series is engineered to withstand harsh industrial conditions, including exposure to dust and water. This ensures durability and reliability in demanding environments.

Application Implementation

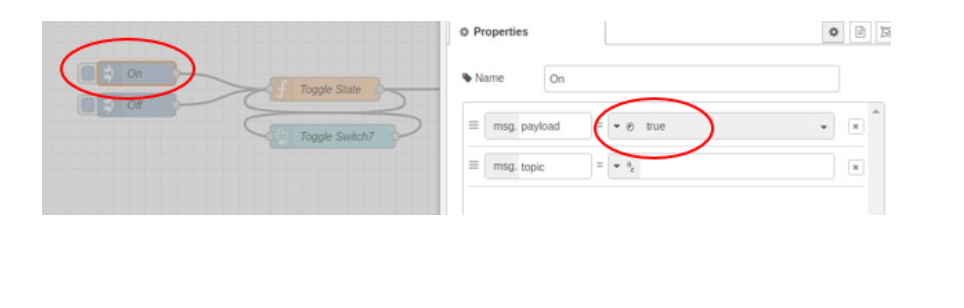

Initialization

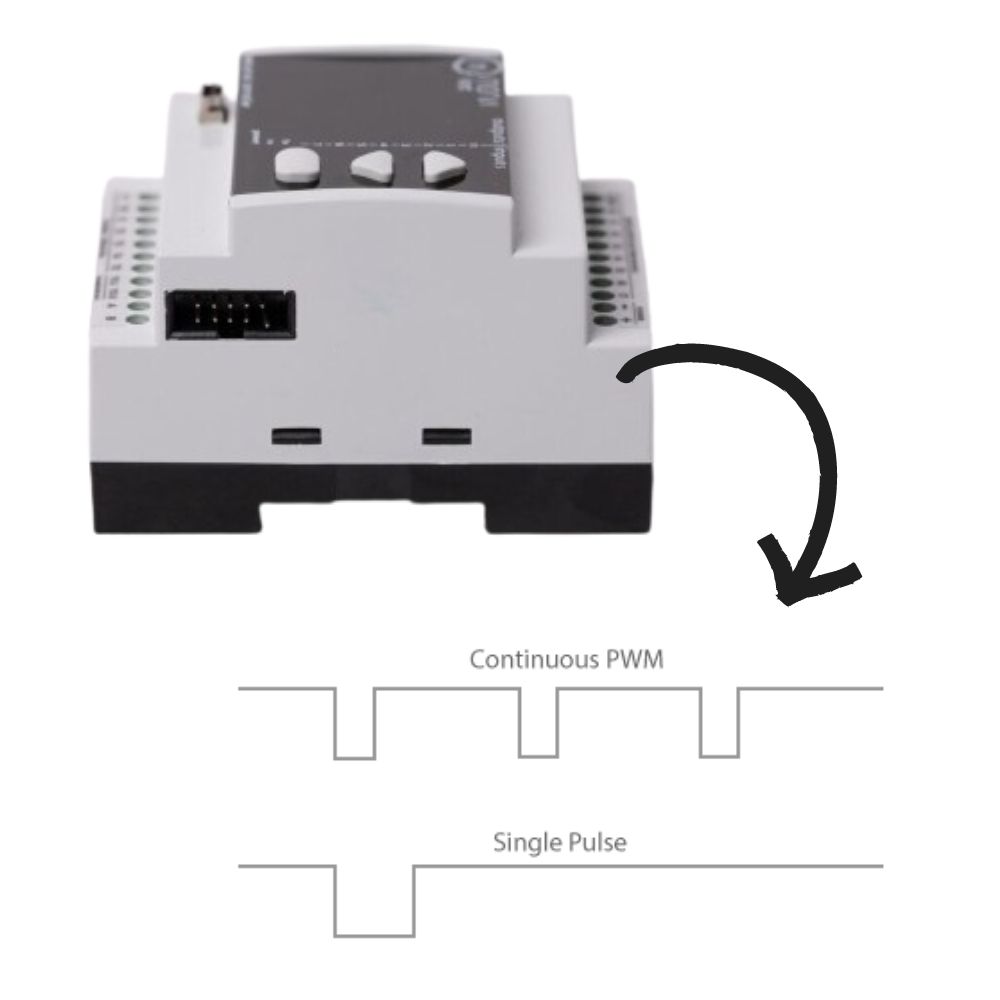

The initial phase of deploying an industrial monitoring application with the M11-E series involves the setup of GPIO (General-Purpose Input/Output), ADC (Analog-to-Digital Converter), and communication interfaces such as RS-485.

Proper initialization ensures accurate data acquisition and reliable communication.

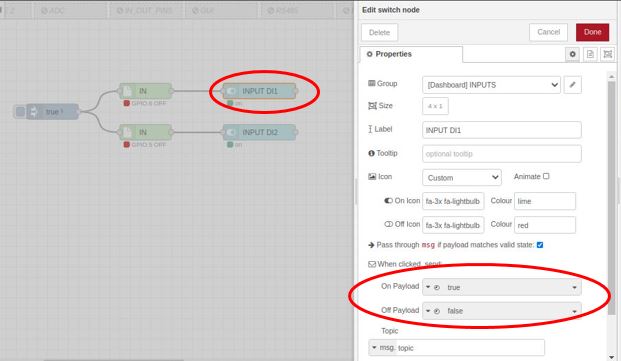

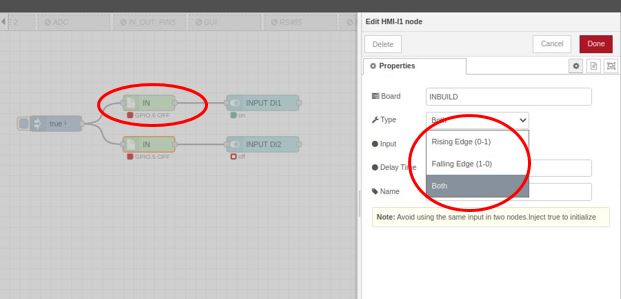

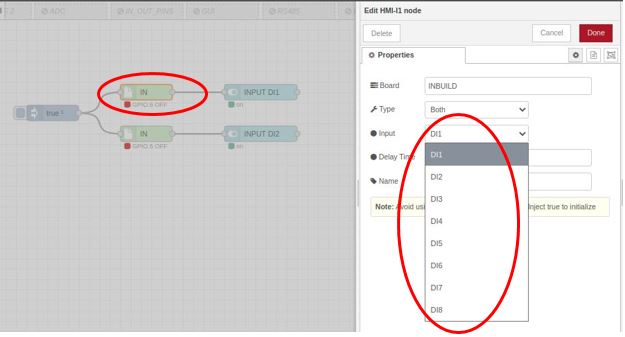

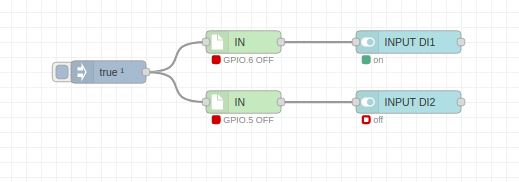

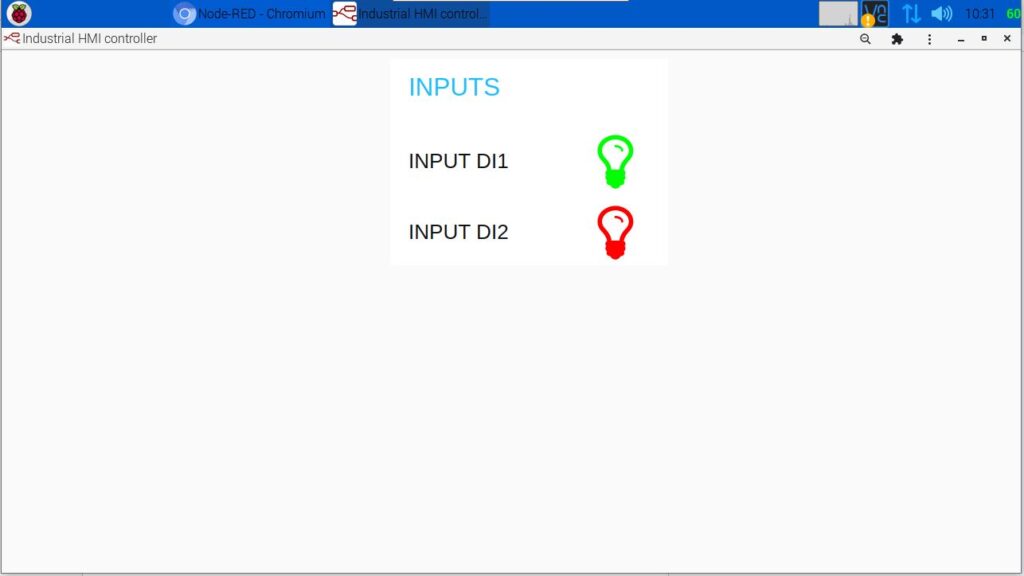

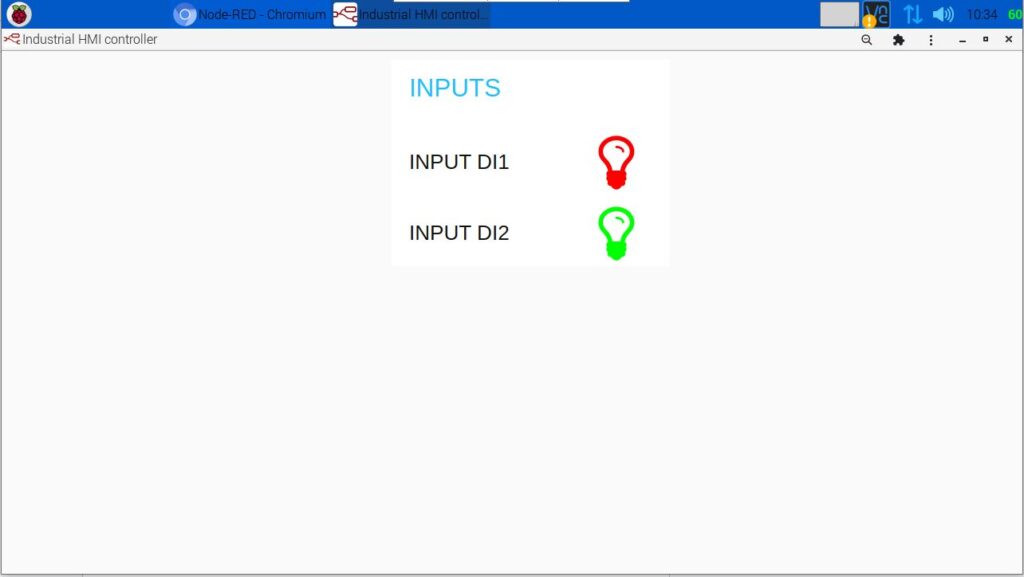

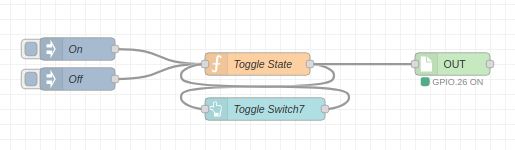

Sensor Data Acquisition

The device periodically samples data from connected sensors.

Digital inputs monitor binary states (e.g., on/off conditions), while analog inputs measure varying signals, providing detailed information about environmental parameters.

Specific models also support data acquisition from load cells, thermocouples, or I2C sensors, tailored to the application requirements.

Data Processing

Once collected, the data undergoes processing and formatting for transmission.

This step includes filtering noise, scaling sensor readings, and converting raw data into actionable metrics.

Proper data processing ensures that the transmitted data is precise and useful for subsequent analysis.

Data Logging

To enhance system reliability, M11-E series devices can log data locally.

This is crucial for scenarios where communication with the remote server is intermittent.

Local data storage ensures no data loss and facilitates data transmission once communication is restored.

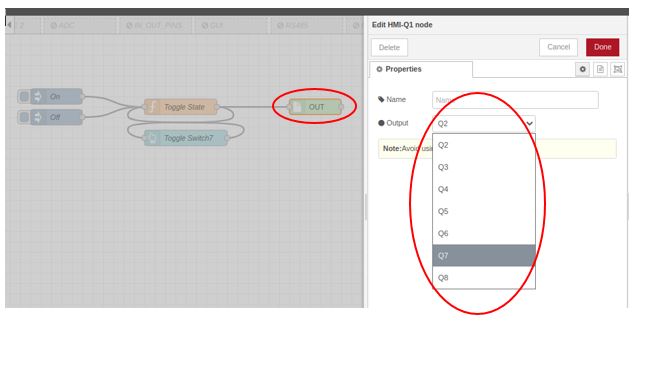

Communication

The processed data is transmitted to a remote server using the chosen communication protocol.

RS-485 offers a stable wired connection for long-distance data transfer, while GSM/LTE and LoRa provide wireless options suitable for different industrial environments.

Ensuring robust communication is essential for real-time monitoring and timely decision-making.

Error Handling

Effective error handling is vital in industrial applications.

The system must detect and manage communication failures, power issues, and sensor malfunctions.

Implementing retry mechanisms, fallbacks, and alerts ensures the system remains operational and reliable.

Power Management

M11-E series devices are designed to operate efficiently within a wide input voltage range.

Monitoring the power supply and managing power consumption is critical to prevent downtime and ensure continuous operation in industrial settings.

Conclusion

The NORVI SSN M11-E series offers a comprehensive solution for industrial grid-powered monitoring applications. Its versatile I/O configurations, robust communication capabilities, and industrial design make it suitable for various industrial environments. Leveraging the ESP32-WROOM32 SoC, these devices provide flexibility, performance, and reliability, essential for modern industrial monitoring needs. Whether monitoring sensor values or parameters from external devices, the M11-E series stands out as a dependable choice for industrial IoT applications.

Visit NORVI M11-E Series Page Now; Here

Or, Contact our Technical support team for all of your technical problems at support@icd.lk