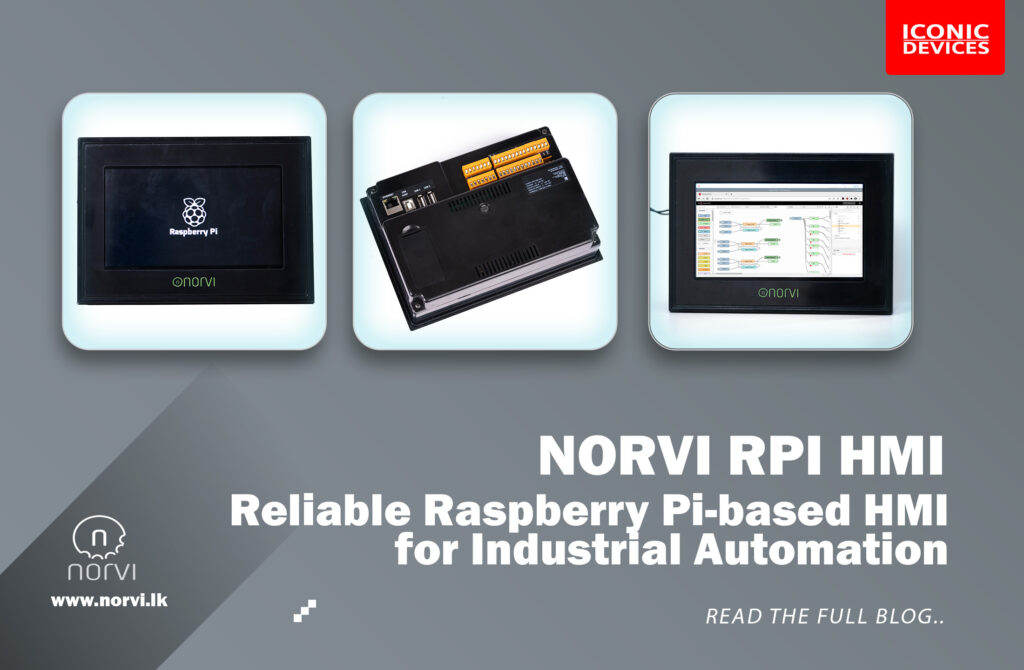

The world of industrial automation is witnessing a significant shift towards connectivity and data-driven decision-making. In this era of Industry 4.0, the Arduino platform has emerged as a popular choice for rapid prototyping and DIY projects due to its ease of use and vast community support. NORVI IIOT takes this compatibility to new heights by seamlessly integrating Arduino’s simplicity with the capabilities required for industrial automation, making it a compelling solution for diverse applications.

NORVI IIOT: Arduino Compatibility Amplified

NORVI IIOT is a revolutionary hardware platform that embraces Arduino compatibility while addressing the specific requirements of industrial automation. It combines the openness and flexibility of Arduino programming with the robustness and reliability necessary for industrial environments, empowering engineers and developers to create advanced automation solutions efficiently.

Key Features and Benefits

- Arduino Compatibility: NORVI IIOT is fully compatible with the Arduino ecosystem, allowing users to leverage the vast library of existing code, tutorials, and community support. This compatibility ensures a smooth transition for Arduino enthusiasts, enabling them to extend their knowledge and skills to industrial automation projects seamlessly.

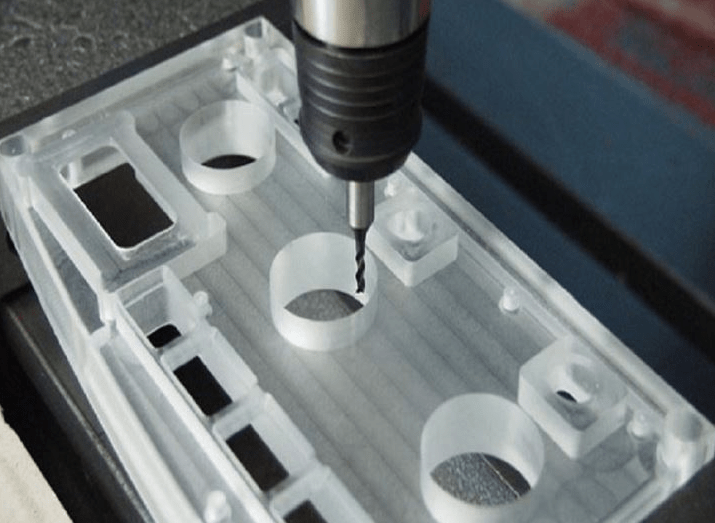

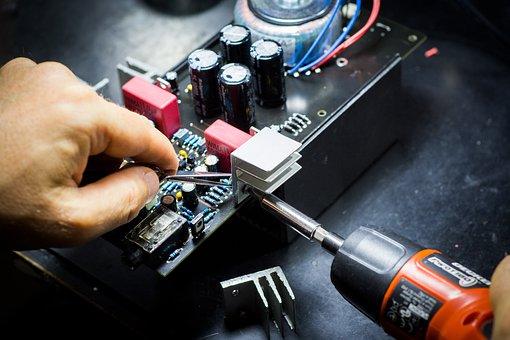

- Industrial-Grade Design: NORVI IIOT is designed to meet the demanding conditions of industrial environments. It incorporates rugged components and adheres to stringent quality standards, ensuring reliable operation in harsh conditions, temperature variations, and electromagnetic interference.

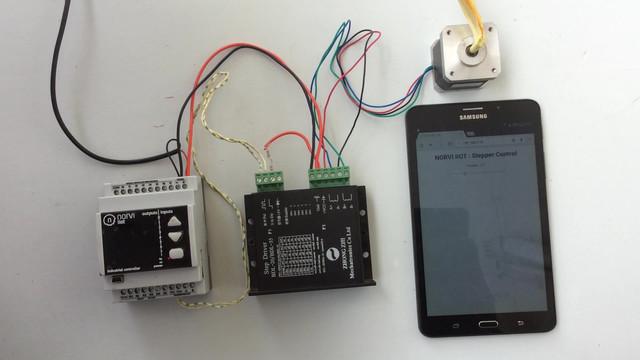

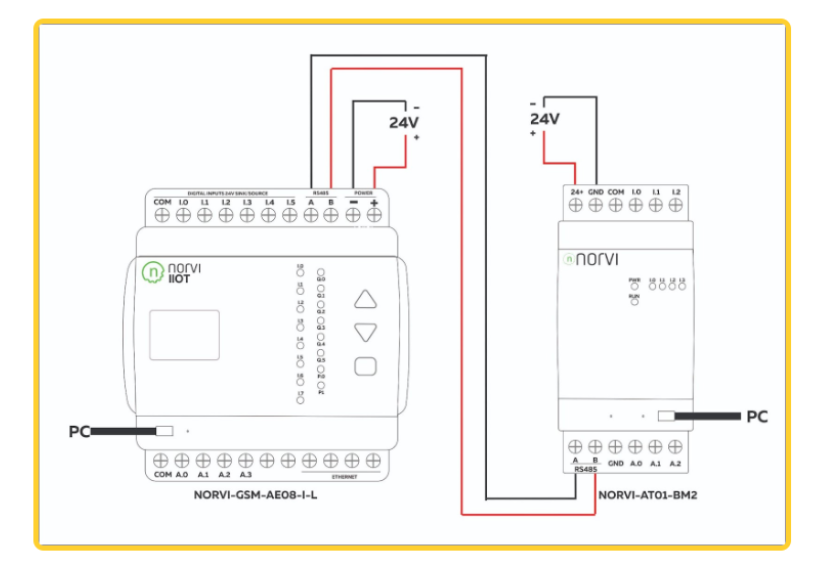

- Extensive I/O Options: NORVI IIOT offers a wide range of input and output options, including digital and analog ports, allowing for easy integration with sensors, actuators, and other industrial devices. This flexibility enables the monitoring and control of various processes, making it suitable for diverse applications across industries.

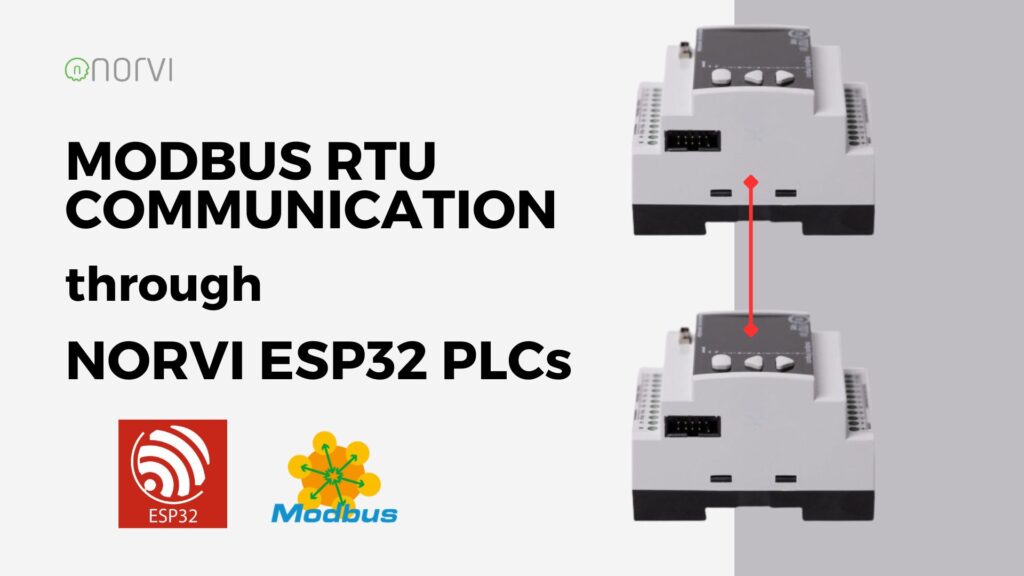

- Communication Protocols: NORVI IIOT supports popular communication protocols such as Modbus, MQTT, and Ethernet/IP, enabling seamless integration with existing industrial networks and protocols. This capability facilitates real-time data exchange, remote monitoring, and integration with supervisory control and data acquisition (SCADA) systems.

- Edge Computing and Analytics: NORVI IIOT is equipped with powerful computational capabilities, enabling edge computing and data analysis at the source. This eliminates the need for transmitting large volumes of data to a central server, enabling real-time decision-making, predictive maintenance, and optimization of industrial processes.

- Scalability and Flexibility: NORVI IIOT is designed to be scalable, allowing users to expand its capabilities by adding additional I/O modules as per project requirements. This scalability ensures future-proofing and adaptability to evolving automation needs, making it a cost-effective choice for both small-scale and large-scale applications.

Applications of NORVI IIOT

- Industrial Automation: NORVI IIOT can be employed in various industrial automation scenarios, including machine control, production line monitoring, and data acquisition. Its Arduino compatibility makes it a versatile solution for rapid prototyping and implementing automation projects across different industries.

- Smart Buildings: NORVI IIOT enables intelligent control and monitoring of building systems such as lighting, HVAC, access control, and energy management. Its compatibility with Arduino allows for customization and integration with smart home automation systems, enhancing energy efficiency and occupant comfort.

- Environmental Monitoring: NORVI IIOT can be utilized for environmental monitoring applications, including air quality sensing, water quality monitoring, and weather stations. Its compatibility with Arduino simplifies the development of monitoring solutions for sustainable resource management and environmental conservation.

- Research and Education: NORVI IIOT’s Arduino compatibility makes it an excellent platform for educational institutions and research labs. It allows students, educators, and researchers to explore and experiment with industrial automation concepts, enhancing their understanding and practical skills.

NORVI IIOT’s compatibility with Arduino offers a powerful combination of simplicity and versatility for industrial automation. By embracing Arduino’s extensive ecosystem, NORVI

The NORVI IIOT, powered by the cutting-edge ESP32-WROOM32 chip is now available for purchase!

Elevate your PLC and IoT experience and explore the limitless possibilities of innovative technology. Get yours today and step into the future of industrial IoT.

Visit our PRODUCT PAGE or, Contact Us at support@icd.lk