You may be wondering why you should choose NORVI Arduino-based PLC. Here is the answer.

NORVI is for creators, who need to integrate technology into their products.

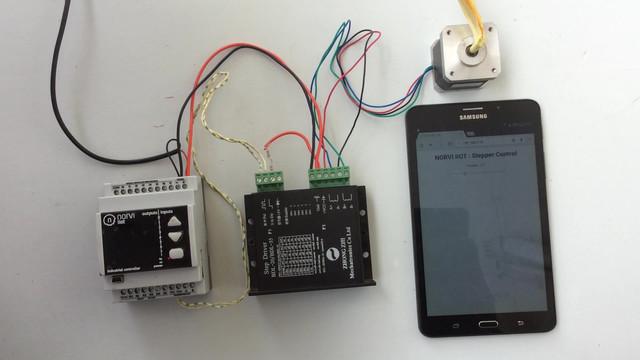

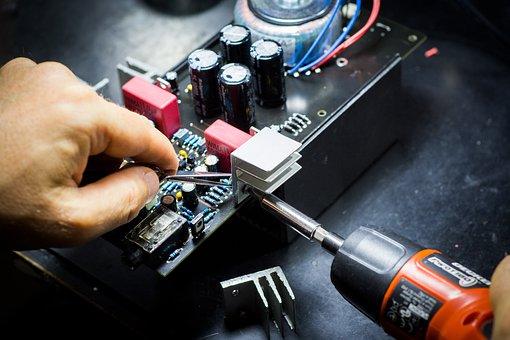

NORVI Arduino-based PLC are popular because they provide a simple and cost-effective solution for creating custom electronic devices and automation systems for you. Also, NORVI controllers are well-known as NORVI Arduino-based PLC (Programmable Logic Controllers). These controllers are easy to program and can interface with a wide variety of sensors and other components, making them ideal for IoT-based solutions such as smart homes, smart cities, smart farming, and asset-tracking applications.

Additionally, the open-source nature of the Programming IDEs means that there is a vast community of developers and enthusiasts constantly creating new projects and sharing knowledge, making it an attractive choice for those looking to expand their connectivity with NORVI controllers for industrial applications. These advancements will enable you to explore and try more professional solutions that can be controlled in real-time in multiple ways and devices using programmable logic controller programming.

7 Reason to Choose NORVI Arduino-based PLC?

NORVI Arduino-based PLC offers a groundbreaking platform for innovative projects due to several key factors:

- Versatility: NORVI’s Arduino-based PLCs are versatile, supporting a wide array of applications across industries. Their adaptability enables integration into various projects and systems.

- Arduino Compatibility: Leveraging the Arduino ecosystem, NORVI PLCs provide a user-friendly interface, extensive libraries, and a vast community for support, fostering ease of development and customization.

- Robust Performance: NORVI PLCs deliver robust performance, offering reliable operation and precise control in industrial and project settings, ensuring efficiency and optimal functionality.

- Scalability: With NORVI, scalability is achievable, allowing expansion or modification of projects without compromising on performance. This scalability caters to evolving project requirements.

- Innovation Support: NORVI’s Arduino-based PLCs encourage innovation by providing a powerful platform with diverse functionalities, enabling developers to explore and implement cutting-edge ideas.

- Reliability and Support: NORVI PLCs come with reliable hardware and comprehensive support, ensuring a seamless experience for users, from development to deployment.

- Cost-Effective Solutions: Offering cost-effective solutions without compromising on quality or performance, NORVI PLCs present an attractive option for a wide range of projects and applications.

In essence, NORVI’s Arduino-based PLCs stand out for their adaptability, performance, scalability, innovation support, and cost-effectiveness, making them an ideal choice for diverse and innovative projects across industries.

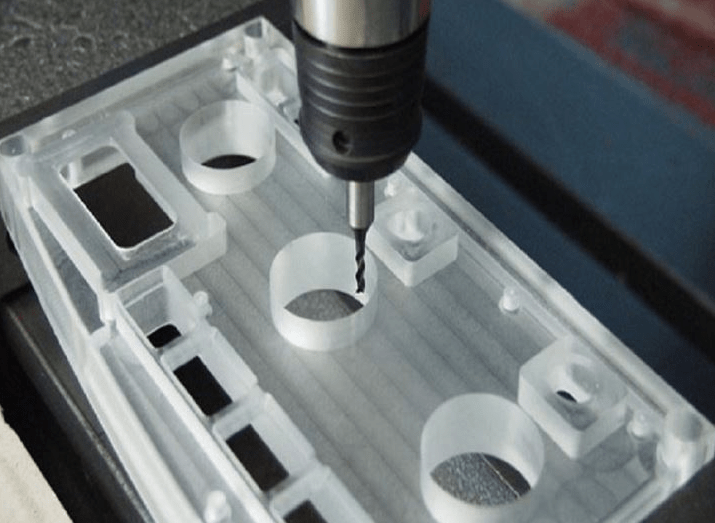

HOW NORVI can be your customized solution?

NORVI comes with customized product solutions where you can choose what exactly you want for your IoT and Automation applications. Those have a Built-in 0.96 OLED Display and a Built-in Button on the front panel. Also, ESP32-WROOM32 and Arduino Micro ATMEGA 32-U4 Module are the main processors of this NORVI series. Which showcases the main advantage for you. Also, SIMCOM SIM800C, QUECTEL EC21-G, and SIM7500 modem selections can be made based on what you need.

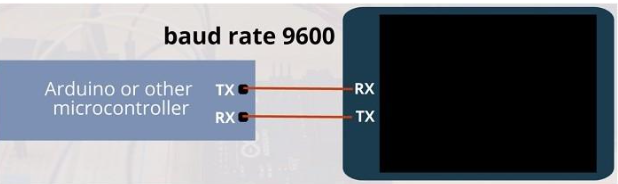

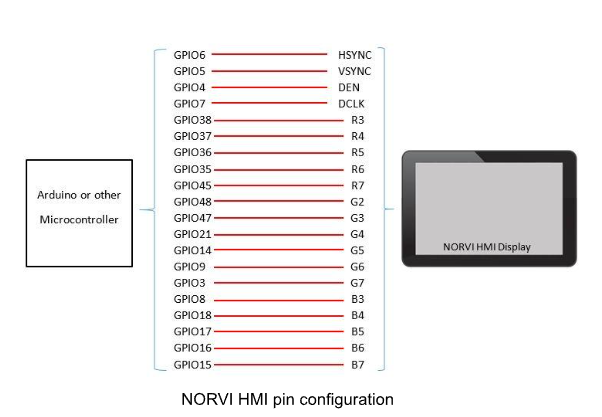

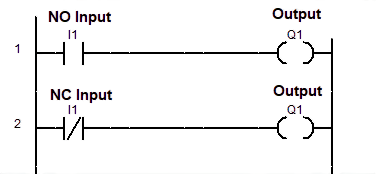

NORVI controllers can also interface with a wide variety of input types, such as digital inputs, analog inputs, Thermocouple inputs, and, PWM 0 – 10V / 4 – 20mA, also with Relay outputs and transistor outputs with RS 485. Also, It enables clients to choose what they want, as it has microSD and RTC module choices. In addition, NORVI controllers can also interface with other types of input devices, such as serial communication devices, Ethernet connections, sim cards, WiFi, Bluetooth, Narrowband IoT (NB-IoT), LoRaWAN, GSM and 4G LTE connections and wireless modules, making them highly versatile and adaptable to a wide range of applications., you can refer our product range.

IoT Range is the best selling category in our product list, you may refer to.

Further, Expansions can be chosen with us as Temperature and load sensor inputs expansions for NORVI IIOT, ENET, and GSM Products also are available with us. Just get what you want with in-build quality controllers with NORVI! Explore More: https://norvi.lk

#Norvi #ArduinoPLC #programmablecontrollers #esp32 #esp32wroom #esp32project #GSM #ethernet #LTE #4GLTE #NBIOT #LoRaWAN #expansions #IoT #iotproject #arduino #smartcontrollers #smartcontrollersystem #smartcontrollersupplier #SmartCities #smartfarming #assettracking #smarthomes #smartapplications #plcapplications #PLC #analog #analoginputs #digitalinputs #pwm #relayoutputs #transistoroutputs #thermocoupleinputs #microsd #rtcmodule #WiFi #bluetooth #mqttdevices