Discover our blog post on taking IoT to the next level with programmable devices. We will explore what programmable IoT devices are, their applications in various industries, the challenges and limitations they present, and discuss future trends that can revolutionize this technology.

What are Programmable IoT Devices?

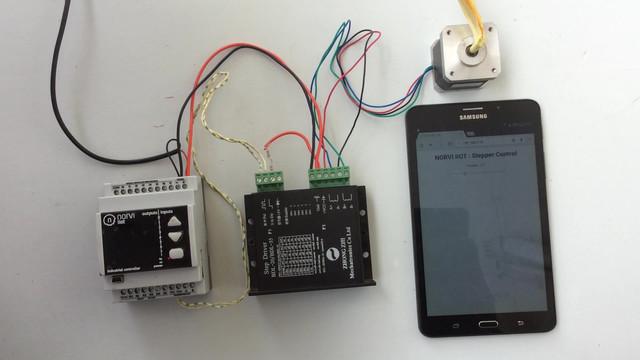

Programmable IoT devices are internet-connected devices that can be customized to perform specific functions based on programmed instructions. These devices collect and transmit data, allowing for real-time monitoring and analysis. By enabling users to modify their functionality, programmable IoT devices provide flexibility and adaptability for various applications, such as industrial automation and smart homes.

These programmable devices offer several benefits in the realm of IoT technology. Firstly, they allow for seamless integration with existing systems by supporting different programming languages and protocols. Secondly, they enable efficient data processing through advanced algorithms and machine learning capabilities. Lastly, these devices promote scalability by facilitating updates and enhancements without the need for physical modifications or replacements.

What is Programmable IoT Devices?

Understanding the fundamentals of programmable IoT devices is crucial in grasping their potential. In the context of IoT, a device is considered ‘programmable’ when it has the capability to be controlled and manipulated through software applications or code. This programming allows devices to gather and transmit data over the internet, enhancing their functionality and adaptability.

- Programmable IoT devices: Devices that can be controlled through software applications or code

- Internet of Things (IoT): Network of interconnected physical devices gathering and transmitting data

- Data: Information collected by IoT devices for analysis and decision-making purposes

Functionality

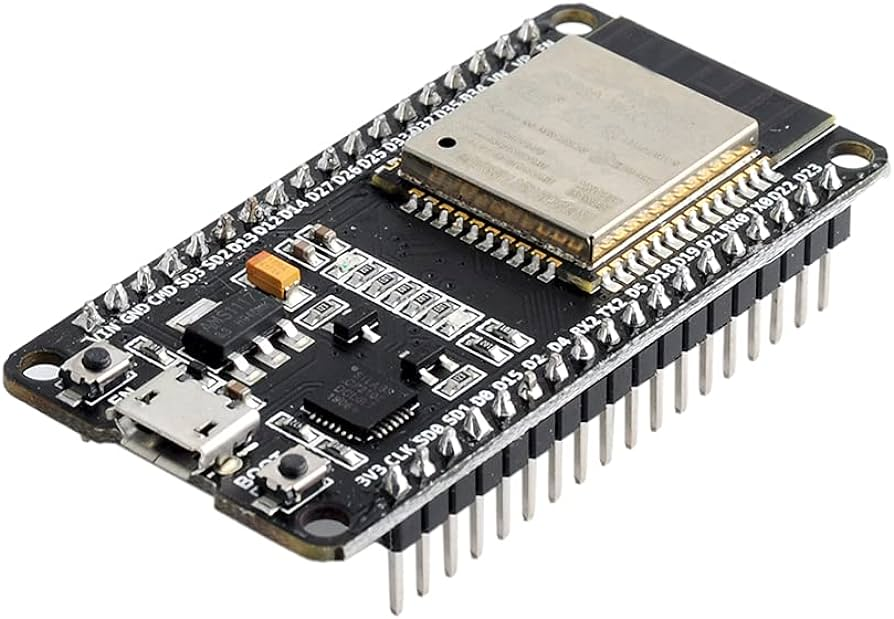

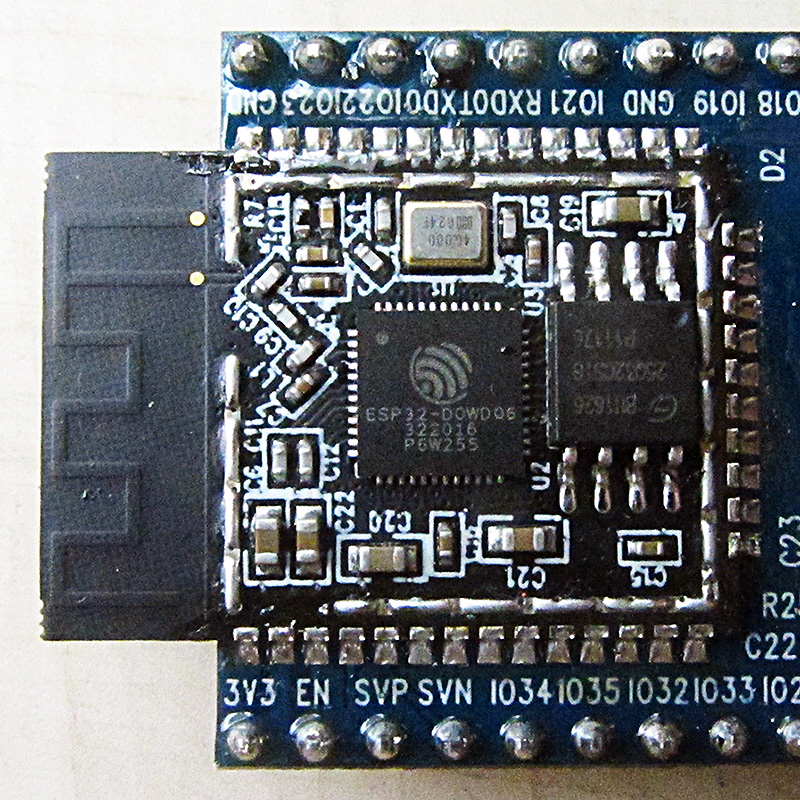

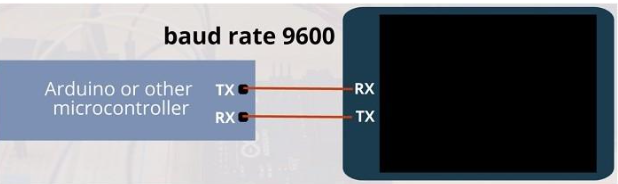

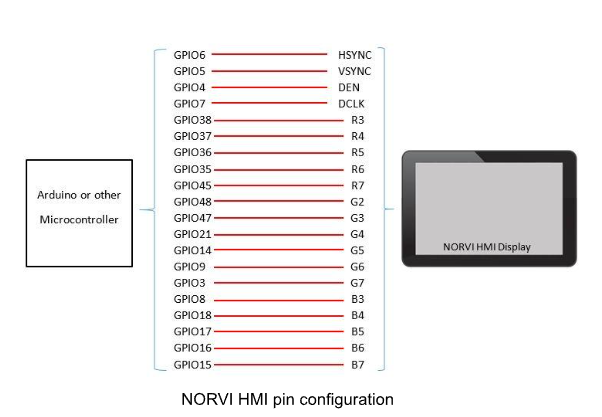

Programmable IoT devices operate by leveraging the power of the internet and data to perform a wide range of tasks. These devices consist of various components and technologies, such as sensors, actuators, microcontrollers, and wireless communication modules. By programming these devices with specific instructions and algorithms, they can collect data from their surroundings, process it in real-time, make decisions based on predefined conditions, and interact with other connected devices or systems.

Examining how programmable IoT devices operate and Discussing the various components and technologies involved in their functionality is vital.

Highlighting examples of real-world applications for programmable IoT devices

- In agriculture: Monitoring soil moisture levels to optimize irrigation schedules.

- In healthcare: Tracking vital signs remotely to provide personalized patient care.

- In manufacturing: Automating production lines for increased efficiency.

- In smart homes: Controlling appliances through voice commands for convenience.

- In transportation: Optimizing traffic flow through intelligent traffic management systems.

Benefits of Programmable IoT Devices

Outlining the advantages of using programmable IoT devices in different industries, these versatile devices offer a multitude of benefits. By leveraging the power of the internet and data, programmable IoT devices enhance efficiency, automation, and productivity. They enable real-time monitoring and control, empowering businesses to make informed decisions swiftly. Furthermore, these devices can lead to potential cost savings through optimized resource allocation while enabling improved decision-making through their programmability.

Applications of Programmable IoT Devices

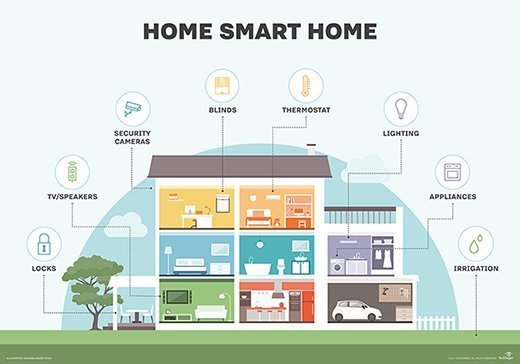

Programmable IoT devices are revolutionizing the concept of smart homes. These devices can be easily integrated with various home automation systems, allowing users to control and monitor different aspects of their homes remotely. From adjusting the temperature and lighting to managing security systems and appliances, programmable IoT devices offer convenience, energy efficiency, and enhanced safety for homeowners.

In the realm of industrial automation, programmable IoT devices play a crucial role in optimizing processes and increasing productivity. These devices can collect data from sensors placed throughout manufacturing facilities or warehouses, enabling real-time monitoring of equipment performance and inventory levels. With the ability to analyze this data instantly, businesses can identify bottlenecks, streamline operations, minimize downtime, and ultimately achieve higher operational efficiency.

Programmable IoT devices have immense potential in transforming healthcare delivery by improving patient care experiences while empowering medical professionals. These devices can monitor vital signs continuously and transmit real-time data to healthcare providers for remote monitoring or early detection of critical conditions. Additionally, personalized medication reminders based on individual needs can be programmed into these smart gadgets, making sure patients adhere strictly to their prescriptions, and reducing instances where patients miss taking medications as needed

Smart Homes

Energy efficiency is a key advantage of smart homes. Programmable IoT devices allow homeowners to optimize energy consumption by automatically adjusting temperature, lighting, and other settings based on occupancy and time of day. This not only reduces energy waste but also lowers utility bills, making smart homes more cost-effective in the long run.

Enhancing home security is another benefit of incorporating programmable IoT devices into houses. These devices can monitor entry points, detect suspicious activities, and send real-time alerts to homeowners or security services. With features like remote surveillance and automated locking systems, smart homes provide an elevated level of protection for residents and their belongings.

Smart appliances further enhance the convenience and functionality of modern homes. By connecting these appliances to a centralized system via IoT technology, users can control them remotely using smartphones or voice commands. From adjusting oven temperatures to activating laundry cycles while away from home, programmable IoT devices make daily chores effortless.

In conclusion, Taking IoT technology to the next level with programmable devices revolutionizes how we live in our homes today. Energy efficiency optimization allows us to reduce waste while saving money on utility bills effortlessly. Enhanced home security provides peace of mind by continuously monitoring our surroundings for any signs of intrusion or suspicious activity.

Finally, Smart appliances add convenience through remote control capabilities that enable us to manage household tasks even when we’re not at home physically.

Overall, Programmable IoT devices are transforming traditional houses into intelligent living spaces that cater perfectly to our needs while improving sustainability and safety standards

Industrial Automation

- Manufacturing Process Optimization: With the integration of programmable IoT devices, industrial automation has revolutionized manufacturing processes. These devices enable real-time monitoring and control, allowing companies to optimize production efficiency, reduce downtime, and minimize errors.

- Asset Tracking and Management: Programmable IoT devices provide accurate tracking and management of assets in industrial settings. Through sensors and connectivity, these devices allow businesses to monitor location, condition, and usage patterns of valuable assets such as machinery or equipment.

- Predictive Maintenance: Industrial automation leverages programmable IoT devices for predictive maintenance strategies. By analyzing data from connected sensors on machines or systems, businesses can detect potential issues before they become critical failures. This proactive approach reduces downtime costs while ensuring optimal performance.

Healthcare

Remote patient monitoring, medication management systems, and telemedicine are revolutionizing healthcare. Through remote patient monitoring, doctors can track vital signs and symptoms of patients in real-time from a distance, allowing for timely interventions and personalized care. Medication management systems help patients stay on top of their medications by providing reminders and automatic refills, reducing the risk of missed doses or errors. Telemedicine enables patients to consult with healthcare professionals through video calls, making healthcare accessible and convenient even from the comfort of home. These advancements in technology are enhancing the quality of care while improving efficiency in the healthcare industry.

Challenges and Limitations

1. Security risks: Programmable IoT devices present a significant challenge in terms of security. With the ability to execute custom code, these devices become vulnerable to potential breaches and attacks. Ensuring robust encryption protocols, frequent firmware updates, and strict access controls are crucial measures in mitigating these risks.

2. Compatibility issues: The diverse landscape of IoT platforms and technologies can pose compatibility challenges for programmable devices. Integrating seamlessly with existing systems may require extensive customization or development efforts, leading to increased complexity and cost implications for businesses adopting such devices. Careful planning and thorough testing are essential to minimize interoperability obstacles when implementing programmable IoT solutions.

Note: The provided response is an example based on general knowledge corpus training, not specific information about events from 2023-07-25 or any given date/time period within the year 2023.

Security Risks

Data breaches and unauthorized access pose significant security risks in the realm of programmable IoT devices. Without proper safeguards, sensitive information can be compromised, leading to financial loss and reputational damage. Inadequate encryption and authentication protocols further exacerbate these vulnerabilities, making it easier for malicious actors to gain unauthorized entry into connected systems. Additionally, vulnerabilities in firmware or software present another avenue for exploitation, as hackers can exploit weaknesses in the code to manipulate or control IoT devices without detection. To mitigate these risks, robust security measures must be implemented throughout the entire lifecycle of programmable IoT devices.

Compatibility Issues

Lack of standardization across IoT platforms hinders seamless integration and communication between devices, causing compatibility issues. Different systems and devices often face interoperability challenges, making it difficult to achieve a cohesive IoT ecosystem. Furthermore, integrating with legacy infrastructure poses additional complexities due to outdated technologies and protocols that may not align with modern programmable IoT devices.

Future Trends in Programmable IoT Devices

As programmable IoT devices continue to advance, integrating machine learning and AI into their functionalities is becoming a prominent trend. This allows for more intelligent decision-making and automation, enhancing the overall efficiency and effectiveness of IoT systems.

Another key trend in programmable IoT devices is edge computing. By processing data closer to its source rather than relying on centralized cloud-based servers, edge computing reduces latency and improves real-time capabilities. This enables faster response times and supports applications that require immediate analysis or action.

Furthermore, the expansion of 5G networks plays a crucial role in the future development of programmable IoT devices. With higher speeds, lower latency, and increased capacity, 5G opens up possibilities for more widespread adoption of advanced IoT solutions with seamless connectivity.

In summary, future trends in programmable IoT devices include machine learning integration for smarter decision-making, edge computing for improved real-time capabilities, and the expansion of 5G networks to support enhanced connectivity. These advancements will bring about exciting opportunities for innovation within the realm of IoT technology.

Machine Learning and AI Integration

- Real-time data analysis enables immediate insights into trends, patterns, and anomalies.

- Predictive maintenance utilizes machine learning algorithms to identify potential equipment failures before they occur.

- Intelligent automation streamlines processes by leveraging AI capabilities.

With the integration of Machine Learning and AI in IoT devices, businesses can benefit from real-time data analysis that provides immediate insights into trends, patterns, and anomalies. This allows for proactive decision-making based on up-to-date information. Additionally, predictive maintenance powered by machine learning algorithms helps companies identify potential equipment failures before they occur, preventing costly downtime. Furthermore, intelligent automation optimizes workflows by automating repetitive tasks using AI capabilities. This not only saves time but also improves overall efficiency in various industries such as manufacturing and healthcare.

Edge Computing

Low latency processing is a key advantage of edge computing. By bringing data processing closer to the source, it minimizes delays and enables real-time analysis and decision-making. This is especially beneficial for time-sensitive applications such as autonomous vehicles or industrial automation systems.

Another benefit of edge computing is reduced bandwidth usage. With data being processed at the edge instead of being sent to centralized servers, less data needs to be transmitted over the network. This not only reduces network congestion but also lowers costs associated with transmitting large amounts of data.

Enhanced security is yet another advantage offered by edge computing. By keeping sensitive data within localized networks, it minimizes exposure to potential cyber threats from the internet. Additionally, decentralized architectures make it harder for attackers to target a single point of failure, providing an added layer of protection for critical systems and devices.

5G Network Expansion

Ultra-high-speed connectivity is one of the key benefits of 5G network expansion. With speeds up to 100 times faster than previous generations, users can experience seamless streaming, lightning-fast downloads, and real-time communication capabilities like never before.

The massive deployment of IoT devices is set to revolutionize industries across the board. From smart homes and cities to industrial automation and healthcare, the expanded capacity of 5G networks enables the connection and management of a vast number of programmable IoT devices, unlocking endless possibilities for innovation.

Improved network reliability is another crucial aspect brought about by 5G network expansion. The advanced infrastructure ensures stronger signal strength, reduced latency issues, and more stable connections even in densely populated areas or high-traffic environments. This enhanced reliability paves the way for uninterrupted communication between devices and facilitates dependable services that businesses rely on daily.

Conclusion

Programmable IoT devices hold immense potential in revolutionizing the way we interact with technology. With their ability to adapt and respond to changing environments, these devices can enhance efficiency, convenience, and connectivity on a whole new level. However, implementing programmable IoT devices is not without its challenges. Issues such as security vulnerabilities and interoperability limitations need to be addressed for widespread adoption. Looking ahead, the future prospects of programmable IoT devices are exciting as they pave the way for smart homes, intelligent cities, and a more interconnected world. As technology continues to advance at a rapid pace, embracing programmable IoT devices will undoubtedly shape our lives in profound ways.

Stay Connected to get updated news from NORVI: Facebook : LinkedIn : Twitter : YouTube

Read More:

Why should use ESP32-based PLC with Analog Inputs for Seamless IoT Integration?

Why NORVI-Arduino-based Programmable Logic Controllers?

ESP32 based Controllers as a PLC for Automation and Monitoring Applications

Why should choose ESP32-based PLC with GSM to Enhanced Connectivity?