Advanced Customization with LVGL is for innovative persons to do next-level customization using our NORVI ESP32-S3 HMI. Let’s explore more about this through this article with examples.

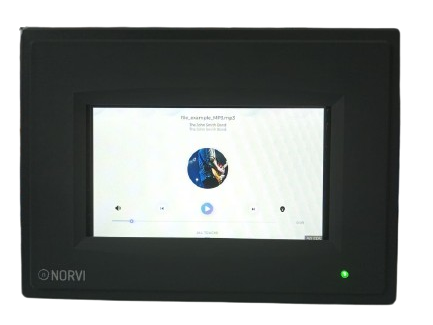

Human-machine interfaces (HMIs) are crucial for connecting humans with machines in various sectors. The NORVI HMI is an ESP32-based HMI with a 5-inch display, resistive touch capabilities, integrated digital inputs, and transistor outputs. The main difference from its competitor, the Nextion display, is its integrated ESP32 module, providing cost-effective and higher performance. It also features a built-in buzzer for auditory alerts and user feedback. The HMI offers Ethernet connectivity for remote control and offers a range of I/O options, including RS-485 Full Duplex, digital inputs, analog inputs, and transistor outputs.

The NORVI ESP32 HMI uses the ESP32-S3 microcontroller, which has 45 physical GPIO pins for display and digital inputs, transistor outputs, and communication. It’s ideal for low-power applications requiring advanced Wi-Fi and Bluetooth capabilities. Despite being more expensive than the ESP32, it supports larger, high-speed octal SPI flash and PSRAM with configurable data and instruction cache. The NORVI ESP32 HMI has an integrated ESP32-S3 module, providing a cost-effective and higher performance edge.

Advanced Customization with LVGL

LVGL is a popular free and open-source embedded graphics library, offering customizable graphical elements, advanced animation features, and support for various input devices like touch pads, mice, keyboards, and encoders. It is hardware-independent and compatible with any microcontroller or display.

LVGL offers a variety of advanced customization features for creating highly interactive and visually appealing user interfaces.

Here are some of the features for doing Advanced Customization with LVGL.

- Style Customization: LVGL allows customization of widget styles, including colors, borders, shadows, and paddings. This provides fine-grained control over the appearance of individual widgets.

- Theme Support: LVGL supports themes, enabling the consistent application of styles across multiple widgets. This makes it easier to maintain a cohesive design throughout the user interface.

- Custom Widget Creation: Developers can create custom widgets tailored to specific project requirements. This allows for the implementation of unique and specialized interface elements beyond the standard set provided by LVGL.

- Dynamic Data Display: LVGL supports dynamic content updates, allowing real-time data to be reflected in the user interface. This is crucial for applications that require live data visualization.

- Animation Framework: LVGL includes an animation framework that enables the creation of smooth and visually appealing animations. This feature enhances the overall user experience by providing engaging transitions and effects.

- Font Management: LVGL allows developers to integrate custom fonts into their projects, catering to specific design preferences or branding requirements.

- Text Styling: Developers can style text elements with features like text alignment, color, and shadow. This enhances the readability and visual appeal of displayed text.

- Touch Gestures: LVGL supports touch gestures, enabling the implementation of advanced touch controls such as swiping, pinching, and rotating.

- Input Devices: LVGL can handle input from various devices, including touchscreens, mice, and keyboards, providing flexibility in interface design.

- Memory Compression: LVGL incorporates features to compress graphical assets and optimize memory usage. This is particularly valuable for projects with limited resources.

- Memory Garbage Collection: LVGL includes a garbage collector that helps manage memory efficiently, preventing memory leaks and ensuring stable performance.

- Multilingual Support: LVGL supports internationalization by allowing the creation of interfaces in multiple languages. This is essential for projects with diverse user bases.

- Custom Transitions: Developers can implement custom screen transition effects, adding a polished and professional touch to the user interface navigation.

- Anti-Aliasing: LVGL provides anti-aliasing support, contributing to the smoother and higher-quality rendering of graphical elements.

- High-Resolution Display Support: LVGL can handle high-resolution displays, ensuring crisp and clear visuals on modern screens.

- Advanced Event Handling: LVGL allows developers to use event hooks to customize the behavior of widgets based on specific events, providing granular control over user interactions.

Conclusion

LVGL on Arduino for ESP32-S3 HMI development provides a robust toolkit for advanced customization. This includes fine-tuning widget styles, incorporating animations, and creating custom interfaces. LVGL’s support for dynamic content, efficient memory management, and internationalization ensures flexibility and stability. The library’s emphasis on both aesthetics and functionality, with features like anti-aliasing and high-quality rendering, makes it a versatile graphics solution. Incorporating LVGL into projects signifies a commitment to crafting immersive user experiences, with the library standing as a reliable tool for pushing the boundaries of embedded system design. Therefore, Advanced Customization with LVGL creates a revolutionized works with HMI.

Low-cost HMI is now available to buy from NORVI.

Visit the Product Page or, Contact Us at [email protected]

Wanna know more about HMI from NORVI? Read below,

The Rise of HMI Applications: Ultimate Tech Landscape

Thriving HMI Technology: Future of Human-Machine Interface

Optimizing HMI Projects for Industrial Automation Success