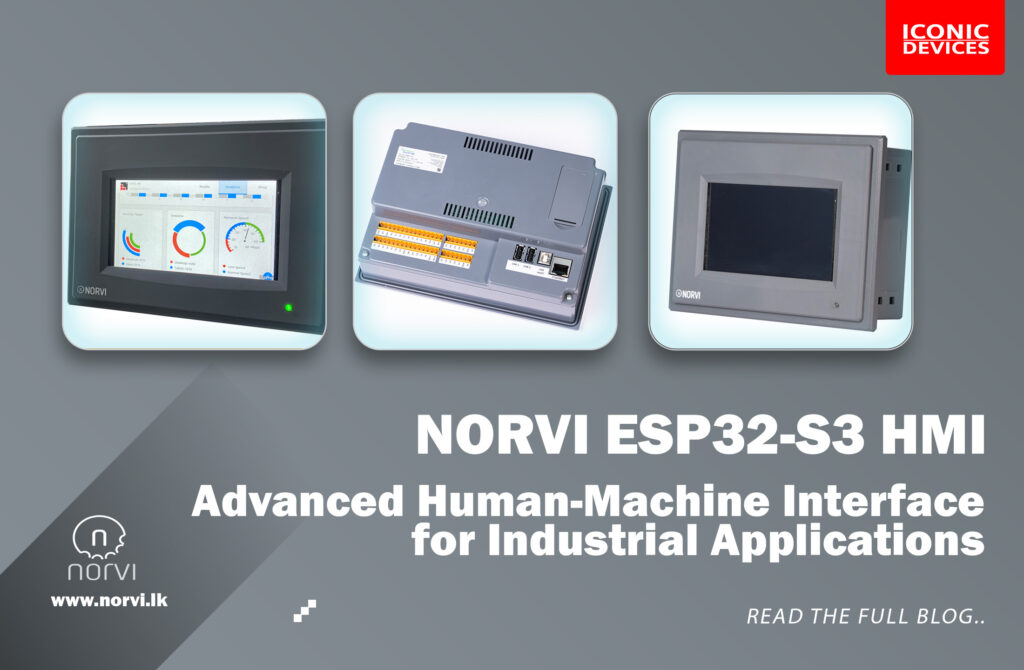

In Industrial Automation, Advanced Human-Machine Interface (HMI) play a crucial role in facilitating control and monitoring of processes.

The NORVI ESP32-S3 HMI is designed to provide a robust, AI-capable interface solution that meets the needs of modern automation systems. Built on the ESP32-S3 platform, this HMI offers unparalleled performance, real-time interaction, and flexibility for various industrial applications.

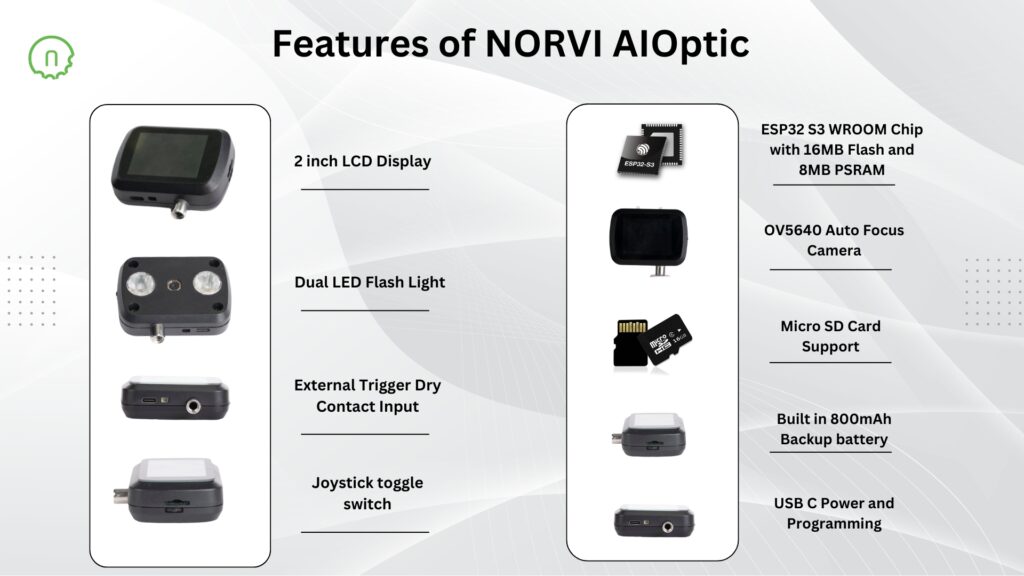

Key Features of NORVI ESP32-S3 HMI

- ESP32-S3 Powered HMI:

Featuring the powerful ESP32-S3 microcontroller with 8MB PSRAM, the NORVI ESP32-S3 HMI offers engineers high performance for edge computing, enabling advanced control systems with minimal latency.

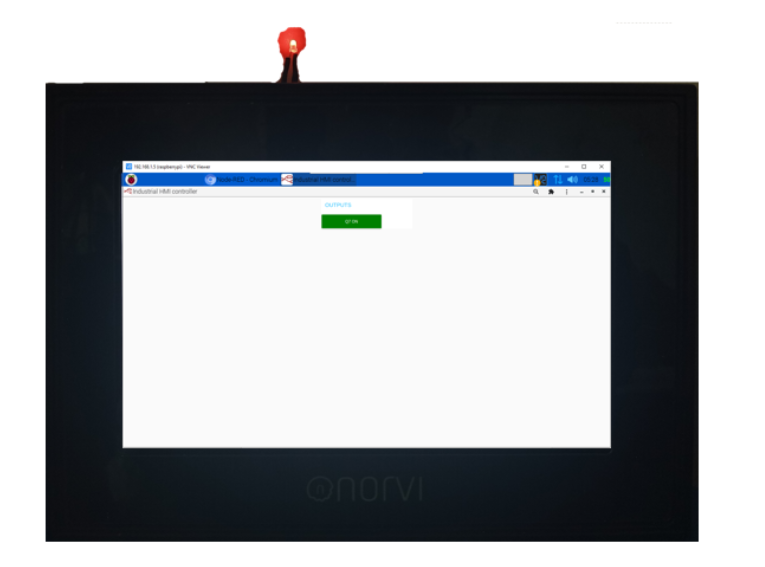

- LVGL Display Integration:

The NORVI ESP32-S3 HMI supports LVGL, an advanced graphics library, ensuring that engineers can build visually intuitive interfaces. This is ideal for creating dynamic control panels and real-time data visualization.

- Comprehensive Connectivity:

Equipped with Wi-Fi and Bluetooth with Ethernet, the NORVI ESP32-S3 HMI allows for seamless integration into existing industrial networks, offering remote control and monitoring capabilities.

Addressing Industry Challenges

- Touch Sensitivity Issues:

Unlike many HMIs that suffer from unreliable touch performance, the NORVI ESP32-S3 HMI delivers accurate, responsive touch input, ensuring smooth interaction in even the harshest industrial environments.

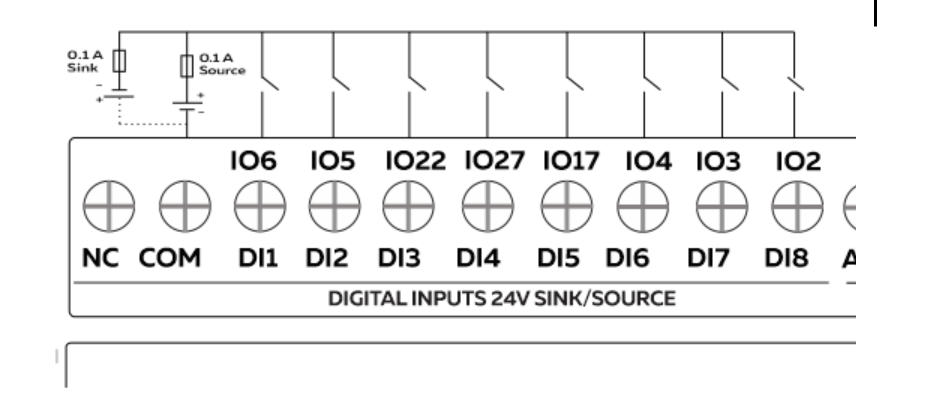

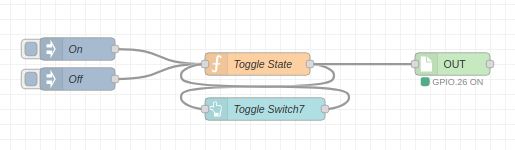

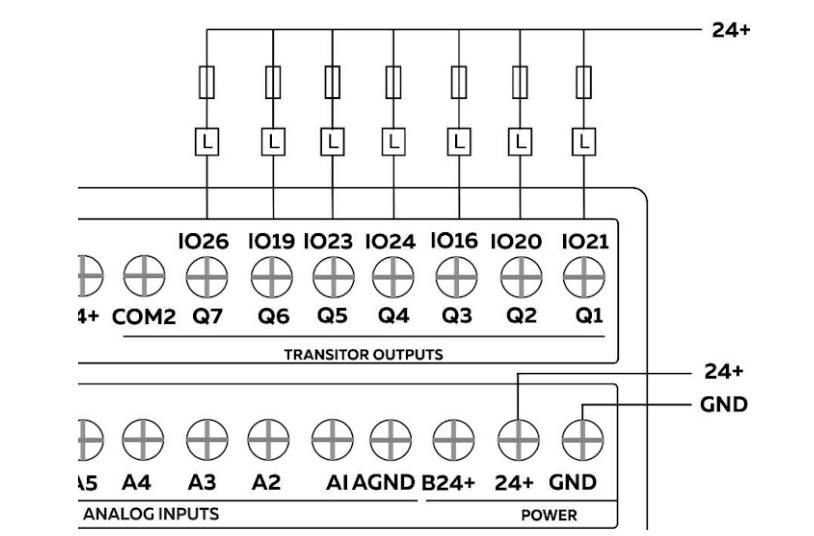

- Limited I/O and Compatibility:

The NORVI ESP32-S3 HMI overcomes compatibility challenges faced by other products by offering versatile I/O options and ensuring seamless integration with industrial equipment.

- Power and Mounting Complexities:

Designed for industrial use, this HMI features a simplified mounting system and is optimized for continuous operation without overheating or power inconsistencies.

The NORVI ESP32-S3 HMI stands out as a cutting-edge solution for industrial automation, delivering powerful performance, real-time interaction, and flexibility. With its ESP32-S3 microcontroller, LVGL display integration, and extensive connectivity options, this HMI ensures efficient control and monitoring across various applications.

Its robust design and responsive touch interface make it ideal for challenging industrial environments, solving common issues such as touch sensitivity and power management. For engineers looking for an advanced, AI-capable HMI, the NORVI Advanced Human-Machine Interface is an optimal choice.

If you need to know more details about NORVI Advanced Human-Machine Interface;

Visit the product Page: https://norvi.lk/esp32-based-hmi-norvi-industrial-arduino-with-lvgl-support/

Contact Us: https://norvi.lk/contact-us/