NORVI Solutions for GSM LTE Connectivity

https://norvi.lk/product/esp32-gsm-series/

Why GSM / LTE in IoT ?

https://norvi.lk/product/esp32-gsm-series/

In the 21st century, IoT connectivity has become a very important thing in many sectors. From human to human and machine to machine and machine to human, IoT application connectivity has become important. From wired and wireless mediums, used for IoT applications to establish connectivity. But wired connectivity has limitations when it comes to remote locations, and the cost increases to develop infrastructure. In this case, GSM/ LTE based IoT applications have become a popular solution. The main reason for using GSM/ LTE based IoT applications is that most GSM/ LTE modems globally use signal bands in GSM, GPRS, WCDMA, LTE-FDD, LTE-TDD. Especially when it comes to NB-IoT based IoT applications, GSM/ LTE are more suitable. Also, GSM / LTE integrated IoT applications consume low power, initial setup is easier, and costs low cost.

Solutions provided by NORVI GSM Series.

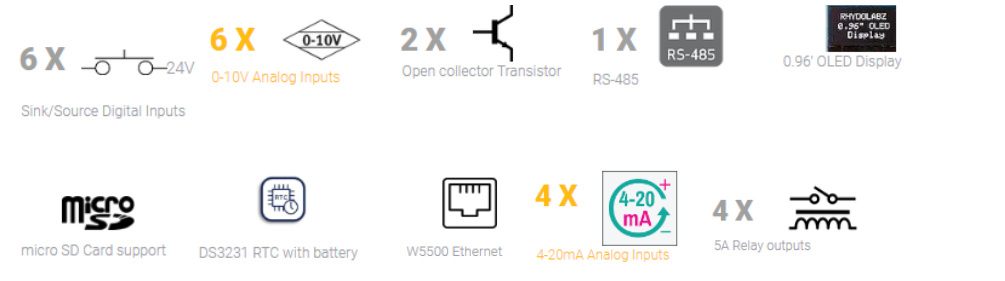

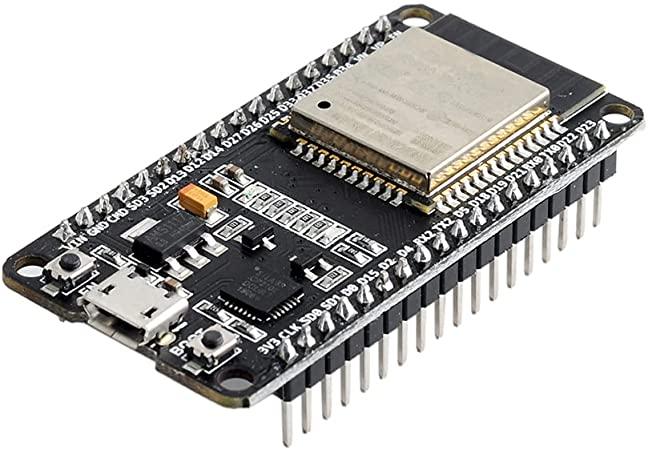

The NORVI GSM series has multiple applications based on IoT. There are SIM800L & QUECTEL EC21-G, two cellular modem types used for implementing NORVI GSM series products. SIM800L integrated NOEVI devices support Quad-band, DTMF, MMS, MUX Functions, Embedded TCP/UDP protocols, 850/900/1800/1900MHz cellular bands, and 12/10 GPRS multi-slot class. When it comes to QUECTEL EC21-G, two cellular modem support on Worldwide LTE, UMTS/HSPA(+) and GSM/GPRS/EDGE, DTMF, MMS, MUX Functions, Embedded TCP/UDP protocols, 850/900/1800/1900MHz cellular bands, 12/10 GPRS multi-slot class.

Applications of GSM based IOT Devices

- Wireless IoT Gateways.

- Data transmission over cellular networks.

- WiFi to GSM Bridge.

- MQTT Gateway.

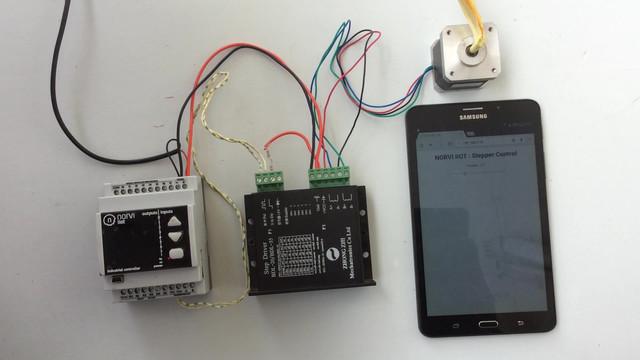

- Remote machine monitoring and controlling.

- Logistic and Store house management.

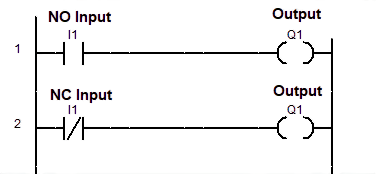

As a wireless IoT gateway case, GSM based NORVI IOT Devices can be used for communicating with multiple devices as a cluster. For data communication with a central server case from a remote location, cellular networks can be used because the modems integrated into the NORVI GSM series support multiple globally recognized cellular bands. For establishing communication between wifi medium media and GSM transmission as a bridge application. As well as control devices via MQTT Gateway provide advantages for industrial and home consumer applications. In an industrial environment, installing GSM based NORVI IOT devices with multiple machine functions can be controlled with a single button press. Furthermore, a large number of industrial machines’ status data can be monitored from a single screen. NORVI GSM based IOT devices can be used to automate & monitor the environmental conditions in store houses and track logistics on a large scale.

Finally NORVI GSM series is a very good low cost wireless communication solution specially for industrial applications.