Discover how Arduino’s accessibility and adaptability have transformed microcontroller programming for hobbyists, students, and enthusiasts. Dive into the crucial realm of Arduino Digital Inputs vs Industrial Arduino Inputs, exploring their pivotal role and comparing them.

Arduino has revolutionized the automation world by making microcontroller programming accessible to hobbyists, students, and enthusiasts. Its ease of use and versatility have spurred widespread adoption for countless projects. One critical aspect of using Arduino boards involves understanding digital inputs and their applications, particularly when comparing them to inputs found in industrial-grade Arduino counterparts.

Understanding Arduino Digital Inputs

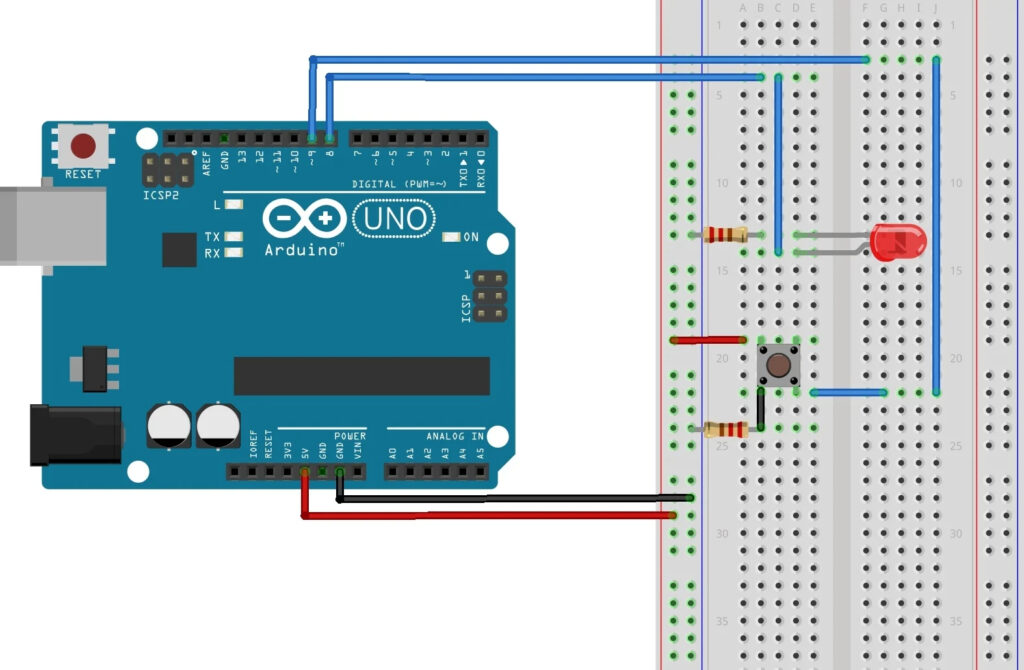

Arduino boards are equipped with an array of digital pins that function flexibly as either inputs or outputs. Specifically, digital inputs perform the pivotal task of interpreting voltage levels, determining the presence of either a HIGH or LOW signal. This adaptability enables them to effectively detect and process signals emanating from a diverse range of sources, including switches, sensors, or other digital devices.

The versatility of Arduino’s digital inputs is a key factor contributing to their widespread applicability across various domains. From facilitating straightforward robotics projects to aiding in the automation of household systems and serving as integral components in educational initiatives, these inputs prove their utility in a multitude of scenarios. Their functionality extends to tasks such as discerning the status of buttons, capturing motion data through sensors, or efficiently receiving signals transmitted by other digital devices.

Moreover, their ease of integration into projects of varying complexities renders them indispensable tools for hobbyists, students, and enthusiasts exploring the realms of electronics and programming. The simplicity with which these inputs can be employed to interface with an extensive array of sensors and devices amplifies their significance in enabling innovation and experimentation within the Arduino ecosystem.

In essence, the adaptability and multifaceted nature of Arduino’s digital inputs not only cater to a wide spectrum of applications, including basic to moderately complex projects, but also serve as foundational elements fostering learning, exploration, and creativity in the realm of microcontroller-based electronics.

Advantages of Arduino Digital Inputs

- Ease of Use: The user-friendly nature of Arduino’s digital inputs is a key attribute that caters to beginners, establishing them as an ideal choice for entry-level projects. Their straightforward configuration and intuitive setup contribute significantly to simplifying the initial learning curve for individuals new to electronics and programming. This accessibility empowers novices to delve into the world of microcontrollers with confidence, fostering a sense of accomplishment and encouraging further exploration and skill development.

- Cost-Effectiveness: Another notable advantage lies in the cost-effectiveness of Arduino boards, which serve as a gateway for hobbyists to experiment without imposing a substantial financial burden. These boards are relatively affordable, ensuring accessibility to a wider demographic and encouraging experimentation and innovation without the constraints of high initial investments. This affordability encourages creativity, enabling enthusiasts to explore various concepts, test ideas, and bring their projects to life without incurring exorbitant expenses.

- Versatility: Moreover, the versatility exhibited by these digital inputs is truly remarkable. Their compatibility with a vast spectrum of sensors and devices extends the horizons of project possibilities, allowing for diverse applications across multiple domains. Whether integrating with temperature sensors, motion detectors, or communication modules, the adaptability of Arduino’s digital inputs facilitates the creation of a wide array of innovative projects, offering endless opportunities for experimentation and customization.

- Community Support: The robust online community surrounding Arduino significantly contributes to its appeal. This vast network provides an abundance of resources, including tutorials, forums, and extensive libraries. Such comprehensive support systems are invaluable assets for users at all skill levels. Beginners benefit from step-by-step tutorials guiding them through their initial projects, while more experienced users can engage in discussions, seek solutions to complex issues, and access a wealth of shared knowledge, further enriching their understanding and capabilities.

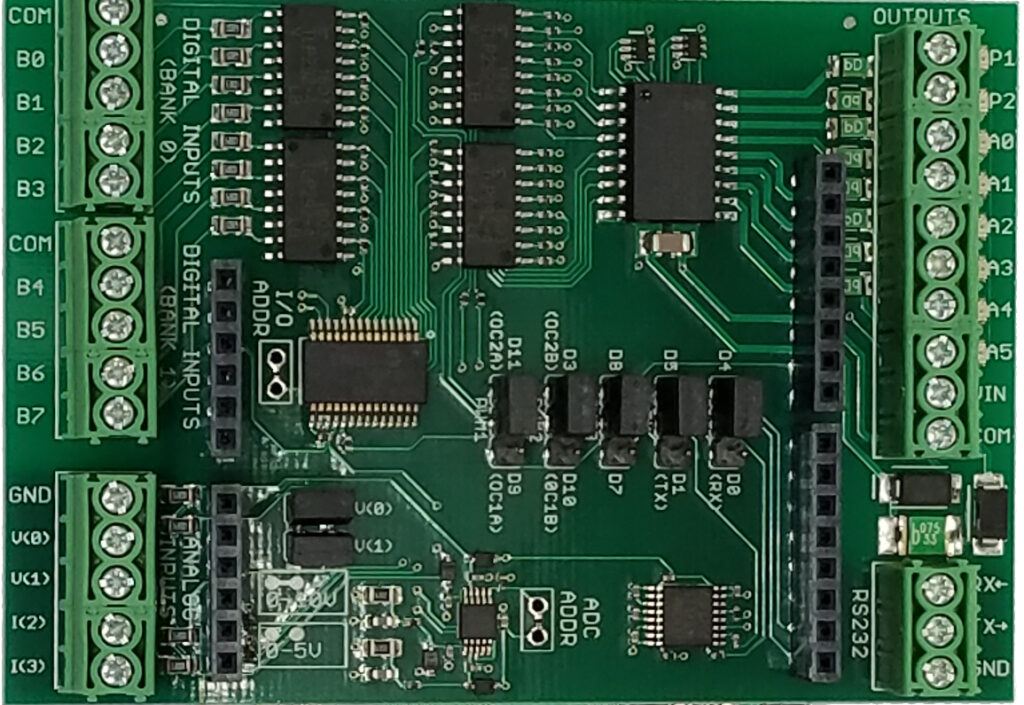

Industrial Arduino Inputs: A Different League

Industrial-grade Arduino boards, such as those produced by reputable brands like Siemens, PLCNext, or Industrial Shields, stand in stark contrast to their standard counterparts, as they are purposefully crafted to withstand the rigors of more demanding and rigorous environments. These specialized boards are meticulously designed to cater to the unique and stringent demands prevalent in industrial settings, distinguishing themselves with their superior durability, reliability, and precision.

One of the hallmark features of these industrial-grade Arduino boards is their inputs, which are engineered with a specific focus on meeting the exacting standards characteristic of industrial applications especially Industrial Arduino Inputs. Unlike standard Arduino inputs, which are adept at serving a broad range of projects, these specialized inputs are purpose-built to operate flawlessly amidst the challenging conditions prevalent in industrial environments.

In industrial settings, reliability is paramount, and these boards are meticulously crafted to ensure consistent performance even in the face of harsh conditions. They boast heightened resilience against temperature fluctuations, electrical noise, and voltage variations, factors that are common in industrial setups. This robustness ensures uninterrupted functionality, mitigating the risk of downtime and potential losses associated with equipment failures.

Durability is another defining characteristic of these industrial-grade boards. Components utilized in their construction are chosen for their ruggedness, ensuring prolonged and reliable operation in challenging and often unforgiving environments. The robust build quality enables these boards to endure harsh conditions where standard electronics might falter, providing a reliable backbone for critical industrial processes.

Furthermore, precision and accuracy are crucial aspects addressed in the design of Industrial Arduino Inputs. They offer superior accuracy in signal readings, a vital requirement for applications that demand precise measurements and high-level accuracy. This attribute makes them indispensable in industries where precise data acquisition is integral, such as in automation, process control, or monitoring systems.

Moreover, many of these specialized industrial-grade Arduino boards undergo stringent certification processes, adhering to industry standards and safety regulations. Compliance with these standards ensures not only reliability but also safety in professional industrial settings, instilling confidence in their deployment for critical applications.

Characteristics of Industrial Arduino Inputs

The distinguishing characteristics of Industrial Arduino Inputs encompass a range of features meticulously tailored to meet the exacting demands of industrial applications, setting them apart from their standard counterparts. These specialized inputs are engineered to deliver unparalleled performance, resilience, and precision in challenging and high-stakes industrial environments.

- Reliability: This stands as a cornerstone attribute of these industrial inputs, underpinning their ability to function consistently amidst the harsh conditions prevalent in industrial settings. Specifically constructed to endure extreme temperature variations, combat electrical noise, and tolerate voltage fluctuations, these inputs exhibit an enhanced tolerance to environmental stresses. This robustness ensures unwavering performance, minimizing the risk of malfunctions or disruptions even in the face of adverse conditions.

- Durability: This is another critical facet that defines the essence of industrial-grade Arduino inputs. These inputs are meticulously crafted using components renowned for their sturdiness and resilience. The choice of rugged materials and construction techniques empowers these inputs to withstand prolonged exposure to challenging environments, guaranteeing sustained and reliable operation over extended periods. This durability is a cornerstone for industries where equipment longevity is paramount to maintain uninterrupted processes.

- Precision and Accuracy: Precision and accuracy in signal readings represent pivotal aspects addressed in the design and calibration of industrial-grade Arduino inputs. These specialized inputs are engineered with a heightened emphasis on delivering superior accuracy, making them indispensable for applications that mandate precise data acquisition. Their ability to provide meticulous and reliable measurements is pivotal in industries such as manufacturing, quality control, and scientific instrumentation.

- Certifications: Compliance with industry standards and certifications is a hallmark feature of many industrial-grade Arduino inputs. These inputs undergo rigorous testing and validation processes to ensure adherence to established standards and safety regulations. This compliance not only underscores their reliability but also guarantees their suitability for deployment in professional settings where adherence to industry protocols is non-negotiable.

Choosing Between the Two

The choice between standard Arduino digital inputs and Industrial Arduino Inputs largely depends on the project’s requirements:

- For hobbyist, educational, or prototyping purposes where cost-effectiveness and ease of use are prioritized, standard Arduino digital inputs are sufficient.

- In industrial settings or projects demanding high reliability, durability, and adherence to specific regulations, industrial-grade Arduino inputs are the preferred choice.

Conclusion

Arduino digital inputs have democratized electronics, empowering countless enthusiasts to explore their creativity. However, when it comes to industrial applications with stringent reliability and durability demands, specialized Industrial Arduino Inputs offer the necessary robustness and precision required for such environments. Understanding the specific needs of a project is crucial in determining which type of Arduino inputs to employ, ensuring optimal performance and reliability in diverse applications.

NORVI offers ESP32-based PLC powered by Arduino and offers Industrial Arduino inputs with many varieties for industrial automation. Visit our product page now: https://norvi.lk/products/

Or, Contact us at [email protected]