- OEM for Embedded Systems

- Electronic Manufacturing Services

- IoT Product Hardware Development

Our Advantages

Experience

We have an experienced team with skills in every phase of IoT product development.

Development tools

Our Research & Development is equipped with tools, prototypes, and test equipment fast forward the development process.

In-house manufacturing & Assembly

In-house manufacturing and assembly makes it save a lot of time, and adds flexibility to the process. We are able to respond to design changes well and workout the best for the project.

NO - MOQ Manufacturing

The investment costs are lowered with No MOQ in manufacturing.

Technical Support

As a product developer, we have worked in many IoT Devices and software platforms. We are committed to providing you the technical support to make your project a success.

Fast Turn Around Time

We have ready to use products, which you can start your concept development on, while a device is being tailor made for you. We ensure the fastest turn around times.

Intellectual Property & Security

Any company that wants to maintain a competitive edge must consider the intellectual Property Security. With NORVI Product development, everything remains in-house. Covering all aspects of IP and Security with a single agreement.

Our Capabilities

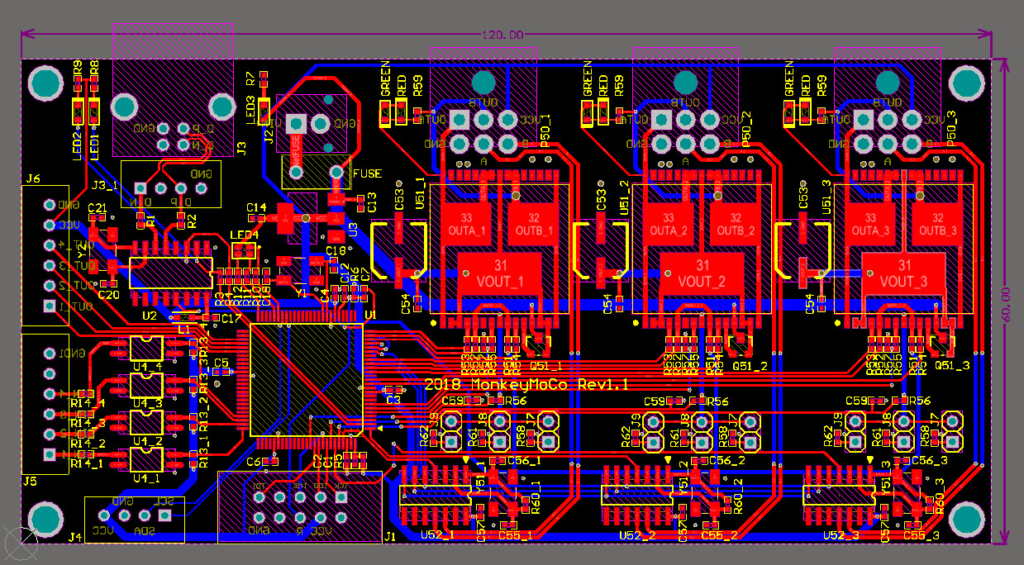

PCB Designing

NORVI’s Printed circuit board (PCB) layout and design services is one of the ways that our customers get to market faster.

Our engineering team has significant real world experience designing PCBs for performance and manufacturability.

We have a proven capability of designing the best and most cost effective IoT Devices.

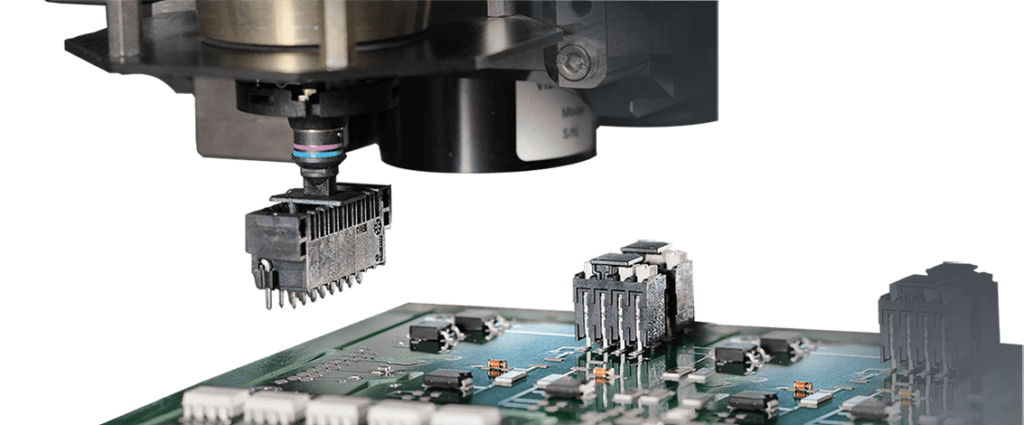

Manufacturing & Assembly

Our process is optimized for the fastest time to market. In-house manufacturing and assembly capabilities, gives more control and speed in the manufacturing process.

In IoT Product development Keeping our process onshore provides hassle free Intellectual Property and Security, in addition to the advantages of flexibility and Speed.

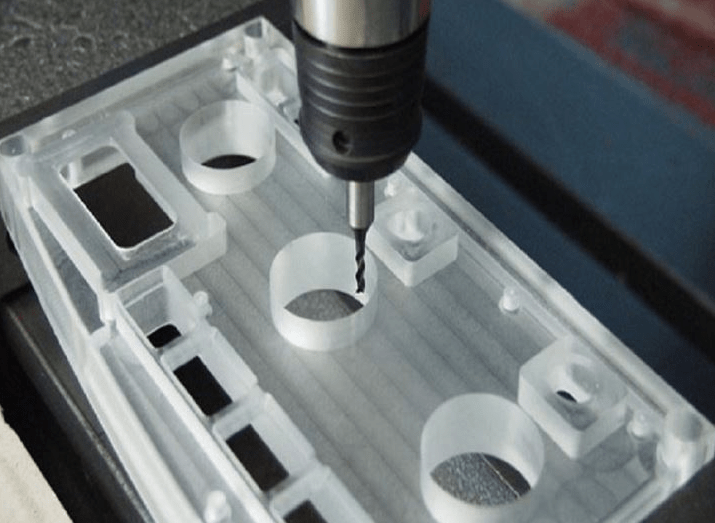

Machining & Printing

Whether its prototype or production unit, we ensure the perfect fit and finish.

With all in-house printing and milling facilities, we are able to print and cut the perfect finish for your product without limitations on production volume.

Our IoT Product Development Stages

Input - Output Identification

As a primary step we identify Input and Output requirements. What it should sense or actuate, decides the hardware we should use within the device.

Our team’s in-depth knowledge of the different types of actuators and sensors, makes you go for the most cost effective and reliable solution.

Communication & Power Source

Communication is the most important part of IoT. Reliable communication methods will be selected, with the power consumption, bandwidth, and cost limitations.

Enclosure - Ingress Protection

We are working with enclosure manufacturers around the world, to provide you the best solutions for enclosing the product for protection.

We work according to the requirements of installation, and environments to deliver a reliable product.

Contact Us | Consultation

Send us a message via [email protected] or below contact form. One of our agents will get back to you.